1.2 5 Mechanical System Efficiency Answers

Onlines

Apr 07, 2025 · 5 min read

Table of Contents

Decoding Mechanical System Efficiency: A Deep Dive into 1.2.5

Understanding mechanical system efficiency is crucial for engineers, designers, and anyone involved in optimizing machinery and processes. This in-depth exploration delves into the intricacies of efficiency, particularly focusing on the context implied by "1.2.5," which suggests a structured learning environment or textbook reference. We'll explore various aspects, clarifying key concepts and providing practical examples to solidify your understanding.

What is Mechanical System Efficiency?

Mechanical system efficiency, often represented as η (eta), quantifies the ratio of useful output work to the total input work. It essentially tells us how effectively a system converts energy input into desired mechanical work. A perfectly efficient system (η = 1 or 100%) would convert all input energy into useful output, but in reality, losses due to friction, heat, and other factors always exist.

Factors Affecting Mechanical Efficiency

Several factors contribute to the overall efficiency of a mechanical system. These include:

-

Friction: Friction between moving parts is a major source of energy loss. It converts kinetic energy into heat, reducing the available output work. The type of surfaces, lubrication, and the design of the system all impact frictional losses.

-

Heat Transfer: Heat generated through friction, deformation, and other processes is lost to the environment. This lost thermal energy reduces the net mechanical output. Efficient heat management, such as through insulation or cooling systems, can mitigate this loss.

-

Internal Resistance: Internal resistance within components, such as in fluid flow through pipes or electrical resistance in motors, diminishes the effective energy transfer. This often manifests as pressure drops or voltage drops respectively, reducing overall efficiency.

-

Misalignment and Wear: Improper alignment of components or wear and tear due to prolonged use can lead to increased friction and energy losses. Regular maintenance and precision manufacturing are crucial for minimizing these effects.

-

Material Properties: The materials used in a mechanical system influence its efficiency. Using materials with high strength-to-weight ratios and low friction coefficients can improve performance and reduce losses.

-

System Design: The overall design of the mechanical system has a profound influence. Factors such as the selection of bearings, gears, and other components, as well as the lubrication system directly affect efficiency.

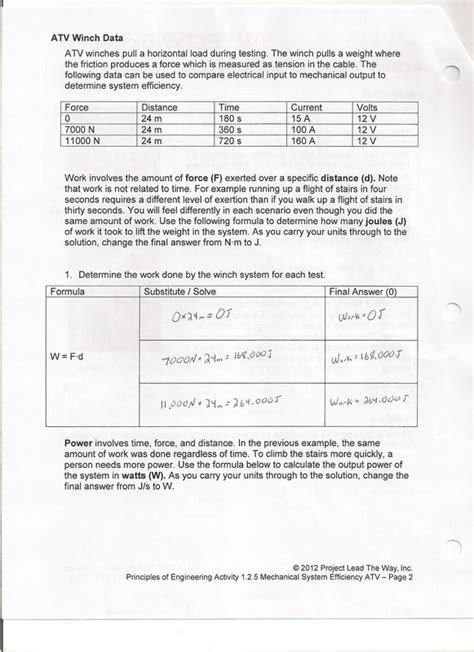

Calculating Mechanical Efficiency

The fundamental formula for calculating mechanical efficiency is:

η = (Useful Output Work / Total Input Work) x 100%

Let's explore different scenarios with specific examples:

Example 1: Simple Machine

Imagine a simple lever system used to lift a 100 kg weight. Suppose you apply a force of 500 N over a distance of 2 meters to lift the weight 1 meter.

-

Input Work: Work = Force x Distance = 500 N x 2 m = 1000 J (Joules)

-

Output Work: Work = Force x Distance = (100 kg x 9.81 m/s²) x 1 m = 981 J (Weight x gravitational acceleration x height lifted)

-

Efficiency: η = (981 J / 1000 J) x 100% = 98.1%

This indicates a highly efficient lever system with minimal energy loss.

Example 2: Gear Train

Consider a gear train with a motor providing 1 kW (kilowatt) of power. The output shaft delivers 800 W of mechanical power to a load.

-

Input Power: 1 kW = 1000 W

-

Output Power: 800 W

-

Efficiency: η = (800 W / 1000 W) x 100% = 80%

This gear train has an efficiency of 80%, implying a 20% energy loss due to friction within the gears and bearings.

Example 3: Hydraulic System

A hydraulic system uses a pump to pressurize a fluid, which drives a hydraulic cylinder. Assume the pump uses 5000 J of energy, and the cylinder performs 4000 J of work.

-

Input Energy: 5000 J

-

Output Work: 4000 J

-

Efficiency: η = (4000 J / 5000 J) x 100% = 80%

Similar to the gear train example, this system also exhibits 80% efficiency.

Improving Mechanical System Efficiency

Optimizing mechanical system efficiency is a multifaceted process involving design improvements, material selection, and maintenance practices. Key strategies include:

-

Reducing Friction: Employing high-quality lubricants, optimizing bearing design, and minimizing contact surfaces can significantly reduce frictional losses. The use of materials with low friction coefficients is also critical.

-

Minimizing Heat Loss: Implementing insulation, employing effective cooling systems, and optimizing the design to minimize heat generation can help to conserve energy.

-

Improving Alignment and Reducing Wear: Regular maintenance, proper alignment of components, and the use of durable materials can minimize wear and tear, reducing energy losses.

-

Optimizing System Design: Careful system design is paramount. This includes selecting components with high efficiency ratings, optimizing component placement to reduce friction and vibration, and ensuring smooth power transmission.

-

Material Selection: Using lightweight, high-strength materials reduces the energy required to move components and improves overall efficiency.

The Significance of "1.2.5" Context

The designation "1.2.5" likely refers to a specific section within a textbook, manual, or course material. Without knowing the specific source, it's difficult to give precise answers. However, this numbering system strongly suggests a hierarchical structure where:

-

1: Represents a major chapter or section (e.g., Mechanics of Machines).

-

2: Represents a sub-section within Chapter 1 (e.g., Power Transmission).

-

5: Represents a specific topic or example within sub-section 1.2 (e.g., Efficiency Calculations for Gear Trains).

To provide truly relevant answers to the "1.2.5 mechanical system efficiency answers," you need to provide the source material for this specific section.

Advanced Concepts in Mechanical Efficiency

Beyond the basic calculations, understanding advanced concepts is crucial for comprehensive efficiency analysis:

-

Isothermal Efficiency: This applies to systems operating at a constant temperature, considering thermodynamic factors.

-

Adiabatic Efficiency: This focuses on systems where no heat transfer occurs during the process.

-

Polytropic Efficiency: A more general efficiency measure considering both heat transfer and work done.

-

Overall System Efficiency: Analyzing the combined efficiency of multiple components within a complex system.

-

Efficiency Mapping: Creating efficiency maps that illustrate the performance across a range of operating conditions.

Conclusion

Mechanical system efficiency is a critical parameter in engineering and design. Understanding the factors affecting efficiency, mastering calculation methods, and employing optimization strategies are essential for creating efficient, cost-effective, and sustainable mechanical systems. While the "1.2.5" context requires further clarification to provide specific tailored responses, the fundamental principles and examples discussed herein provide a strong foundation for a deeper understanding of this important topic. Remember that continuous improvement and attention to detail are crucial for maximizing the efficiency of any mechanical system.

Latest Posts

Latest Posts

-

Exercise 35a The Lymphatic System And Immune Response

Apr 10, 2025

-

If Trauma Is Suspected During Cpr

Apr 10, 2025

-

What Are The Itis Estimation Models Available In Iest

Apr 10, 2025

-

Fluency And Skills Practice Lesson 1 Answer Key

Apr 10, 2025

-

What Protein Is Matched With Its Function

Apr 10, 2025

Related Post

Thank you for visiting our website which covers about 1.2 5 Mechanical System Efficiency Answers . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.