A Mass Customization Strategy Seeks To Blank______.

Onlines

Mar 22, 2025 · 6 min read

Table of Contents

A Mass Customization Strategy Seeks to Maximize Individuality While Maintaining Efficiency

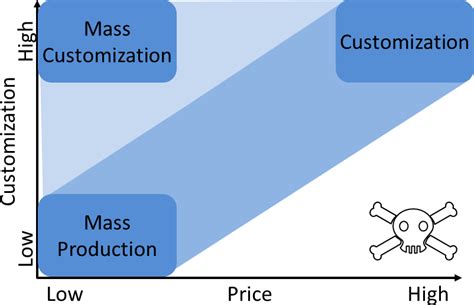

Mass customization, a seemingly paradoxical concept, aims to achieve a delicate balance: offering highly individualized products or services while maintaining the efficiency and cost-effectiveness of mass production. It's not simply about offering a range of choices; it's about dynamically tailoring the production process to meet the specific needs of each customer, almost as if manufacturing on a mass scale were personalized. This strategy seeks to bridge the gap between the uniformity of mass production and the uniqueness of bespoke craftsmanship. This article will delve deep into the multifaceted goals of a mass customization strategy, exploring its core principles, practical applications, and the challenges involved in its successful implementation.

The Core Principles of Mass Customization

At its heart, a mass customization strategy seeks to:

1. Deliver Personalized Products or Services:

This is the most fundamental goal. The strategy isn't about offering a limited set of options; it's about empowering customers to design products or services to their exact specifications. This could range from selecting colors and materials to specifying functional features and even incorporating personalized messages or designs. Think of it as a spectrum, moving beyond simple customization choices (like choosing the color of a car) to truly bespoke solutions.

2. Maintain Cost-Effectiveness:

This is where the "magic" of mass customization lies. The strategy acknowledges that true bespoke production is incredibly expensive. Mass customization aims to leverage economies of scale inherent in mass production while retaining the flexibility to personalize individual units. This requires streamlining production processes, utilizing advanced technologies, and optimizing supply chain management. Cost-effectiveness isn't about sacrificing quality; it's about achieving optimal value for both the producer and the consumer.

3. Enhance Customer Satisfaction:

By delivering products or services that perfectly match individual needs and preferences, mass customization inherently leads to higher customer satisfaction. Customers feel valued, heard, and empowered. This translates into increased brand loyalty, positive word-of-mouth marketing, and ultimately, stronger business growth. This aspect goes beyond mere functionality; it taps into a customer's emotional connection with the product.

4. Increase Market Share and Competitive Advantage:

In increasingly competitive marketplaces, offering personalized experiences becomes a powerful differentiator. Mass customization allows businesses to cater to niche markets and cater to a wider range of customer preferences than traditional mass production. This enhanced market reach can lead to significant growth and a stronger competitive edge.

5. Reduce Waste and Improve Efficiency:

A well-executed mass customization strategy reduces waste by producing only what's needed. Unlike traditional mass production where significant quantities of unsold inventory might be discarded, mass customization minimizes overproduction. Furthermore, technological advancements and efficient production processes play a key role in improving overall efficiency.

6. Build Strong Customer Relationships:

The personalization inherent in mass customization fosters stronger customer relationships. By engaging customers in the design and production process, businesses create a deeper level of connection and loyalty. This level of engagement can lead to valuable customer feedback, improving future product iterations and overall business strategy.

Key Strategies for Implementing Mass Customization

Successfully implementing a mass customization strategy requires careful planning and execution. Several key strategies contribute to its success:

1. Modular Design:

Modular design is crucial. This approach breaks down products into independent modules or components that can be easily combined and configured in various ways. This allows for a vast number of personalized combinations without requiring the design and manufacturing of each individual product from scratch. This reduces complexity and cost while allowing for significant flexibility.

2. Advanced Technologies:

Technologies like Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), and sophisticated software systems are essential. These tools streamline the design, manufacturing, and management processes, enabling efficient handling of individual customer requests. Automation plays a vital role in maintaining cost-effectiveness. 3D printing, for example, is revolutionizing the ability to produce highly customized products on a smaller scale.

3. Efficient Supply Chain Management:

A robust and agile supply chain is crucial. It needs to be capable of sourcing and delivering the necessary components quickly and efficiently to meet individual customer demands. Real-time inventory management and predictive analytics play a critical role in optimizing the supply chain's responsiveness.

4. Customer Relationship Management (CRM):

CRM systems are crucial for capturing, managing, and analyzing customer data. This data is essential for understanding customer preferences and tailoring the offerings accordingly. It allows for better communication and personalization throughout the customer journey.

5. Agile Manufacturing:

Agile manufacturing principles emphasize flexibility and responsiveness. Production processes need to be adaptive and capable of switching quickly between different product configurations to cater to individual customer needs. This requires a lean and efficient manufacturing environment.

Challenges in Implementing Mass Customization

While the potential benefits are significant, mass customization presents several challenges:

1. Increased Complexity:

Managing a wider variety of product configurations significantly increases the complexity of the production process. This complexity needs to be addressed through careful planning, efficient technology, and a highly skilled workforce.

2. Higher Initial Investment:

Implementing the necessary technologies and systems requires a substantial upfront investment. This can be a barrier for smaller businesses with limited resources.

3. Inventory Management:

Balancing the need for personalized products with efficient inventory management is crucial. Holding large quantities of every possible component is impractical, requiring sophisticated demand forecasting and supply chain strategies.

4. Customer Communication and Collaboration:

Effective communication and collaboration with customers are critical. Clear processes for capturing customer requirements and providing updates throughout the production process are essential to manage expectations and build trust.

Examples of Mass Customization in Action

Many industries are successfully employing mass customization strategies:

- Apparel: Online retailers allow customers to personalize clothing with custom designs, fabrics, and fittings.

- Footwear: Companies offer customized shoe designs with varying materials, sizes, and features.

- Automotive: Car manufacturers allow customers to customize their vehicles' color, interior, features, and accessories.

- Software: Software companies offer customizable software solutions to cater to specific business needs.

- Furniture: Businesses enable customers to choose materials, colors, and dimensions for their furniture.

The Future of Mass Customization

Mass customization is constantly evolving. Emerging technologies like artificial intelligence (AI), machine learning (ML), and advanced robotics are further enhancing its capabilities. AI-powered design tools can help customers visualize and design their personalized products, while advanced robotics and automation improve production efficiency and reduce costs. The integration of these technologies will likely lead to even more personalized and efficient mass customization solutions in the future.

Conclusion

A mass customization strategy seeks to maximize individuality while maintaining efficiency. It's a sophisticated approach that requires a blend of strategic planning, technological capabilities, and a deep understanding of customer needs. While challenges exist, the potential rewards – increased customer satisfaction, stronger brand loyalty, and a significant competitive advantage – make it a compelling strategy for businesses aiming to thrive in today's dynamic marketplaces. The future of mass customization promises even more personalized and seamless experiences, driven by the relentless advancement of technology and an ever-growing customer demand for unique and tailored solutions.

Latest Posts

Latest Posts

-

Ati Diagnostic Template For Vital Signs

Mar 23, 2025

-

What Happens If You Put Hand Sanitizer In Your Hair

Mar 23, 2025

-

Risk Or Reward Chapter 7 Lesson 6

Mar 23, 2025

-

When You Evaluate An Online Document For Sponsorship You Should

Mar 23, 2025

-

Amoeba Sisters Video Recap Multiple Alleles Blood Types

Mar 23, 2025

Related Post

Thank you for visiting our website which covers about A Mass Customization Strategy Seeks To Blank______. . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.