A Sample Of Brass Weighing 1.203 Grams

Onlines

Apr 01, 2025 · 6 min read

Table of Contents

A Sample of Brass Weighing 1.203 Grams: A Deep Dive into Material Analysis

This seemingly insignificant amount of brass – 1.203 grams – holds a wealth of information for those who know where to look. This article will explore the various analytical techniques used to characterize this small brass sample, detailing the properties that can be determined and their implications. We'll delve into the world of material science, examining the composition, microstructure, and potential applications based on this seemingly minuscule quantity.

The Significance of a Small Sample

While a larger sample would certainly allow for more extensive testing, even a 1.203-gram sample of brass offers surprising analytical possibilities. Miniaturization in analytical techniques has made it possible to perform detailed characterization on samples of this size, often with impressive accuracy. This opens doors to research and analysis where large samples might be unavailable or impractical to obtain.

Brass Composition: Unraveling the Alloy

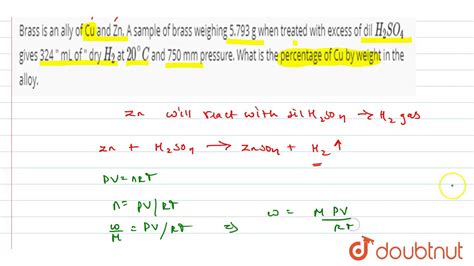

Brass is a copper-zinc alloy, and the exact proportions of these two elements significantly influence its properties. The first step in characterizing our 1.203-gram sample would involve determining its precise composition. Several techniques are well-suited for this purpose:

1. X-ray Fluorescence (XRF) Spectroscopy: A Non-Destructive Approach

XRF is a powerful non-destructive technique that can determine the elemental composition of a material. It works by irradiating the sample with X-rays, causing the atoms to emit characteristic X-rays. By analyzing the energy and intensity of these emitted X-rays, we can identify and quantify the elements present. This is particularly useful for our small sample because it doesn't require any sample preparation that might cause damage or loss of material. The XRF analysis would reveal the precise percentages of copper and zinc, as well as any trace elements that might be present.

2. Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES): High Sensitivity Analysis

ICP-OES provides highly sensitive elemental analysis. A small portion of the 1.203-gram sample would be dissolved in a suitable acid, and the resulting solution is then introduced into an inductively coupled plasma (ICP). The excited atoms in the plasma emit light at characteristic wavelengths, which are then measured to determine the elemental composition. ICP-OES offers excellent sensitivity and can detect trace elements present in even minute concentrations within our brass sample. This method allows for precise quantification of the copper and zinc, providing a highly accurate composition profile.

3. Atomic Absorption Spectroscopy (AAS): Specific Element Quantification

AAS is another technique that can be used for precise quantification of the copper and zinc in the brass sample. Similar to ICP-OES, a small portion of the sample needs to be dissolved. The resulting solution is then aspirated into a flame or graphite furnace, where the analyte atoms absorb light at specific wavelengths. The amount of light absorbed is directly proportional to the concentration of the analyte. AAS is particularly useful for determining the concentration of specific elements, making it a valuable tool for verifying the results obtained from XRF or ICP-OES.

Microstructure Analysis: Unveiling the Internal Structure

The microstructure of the brass significantly impacts its mechanical properties, such as strength and ductility. Analyzing the microstructure of our 1.203-gram sample requires techniques capable of handling small specimens:

1. Optical Microscopy: Visualizing the Grain Structure

A small section of the brass sample can be carefully prepared using standard metallographic techniques (cutting, grinding, polishing, and etching). This prepared sample can then be examined under an optical microscope. The optical microscope will reveal the grain size, grain shape, and presence of any phases or inclusions. The grain size is a key indicator of the brass's mechanical properties. A finer grain size generally results in higher strength and hardness. The presence of other phases, such as precipitates, can also affect the material's properties.

2. Scanning Electron Microscopy (SEM): High-Resolution Imaging

SEM provides higher resolution imaging than optical microscopy, allowing for more detailed observation of the microstructure. A small piece of the brass sample is mounted, coated with a conductive material, and then placed in the SEM chamber. The SEM uses a focused beam of electrons to scan the surface of the sample, generating images with high magnification and depth of field. This can reveal fine details of the grain structure, such as grain boundaries and the presence of any microstructural features. SEM can also be combined with Energy-Dispersive X-ray Spectroscopy (EDS) for elemental analysis of specific regions within the microstructure.

3. Transmission Electron Microscopy (TEM): Atomic-Level Details

For the most detailed analysis, TEM can be employed. TEM involves transmitting a beam of electrons through an extremely thin sample. This technique can reveal the atomic-level structure of the brass, providing information on crystal defects, lattice structure, and the arrangement of atoms within the grains. While requiring even more sample preparation, TEM is useful for resolving very fine details relevant to mechanical and physical properties.

Mechanical Properties Testing: Assessing Performance

Despite the limited sample size, some mechanical properties of the brass can still be assessed, albeit with limitations:

1. Microhardness Testing: Measuring Hardness

Microhardness testing involves indenting the sample's surface with a small indenter and measuring the size of the indentation. This provides a measure of the material's hardness. Specialized microhardness testers are available that can accommodate very small samples. The hardness value provides insights into the strength and wear resistance of the brass.

2. Nanoindentation: Probing at the Nanoscale

Nanoindentation uses an even smaller indenter to probe the mechanical properties at the nanoscale. This technique is particularly valuable for very small samples and allows for the determination of hardness and elastic modulus at different locations within the sample. Nanoindentation can also provide information on the material's plastic deformation behavior.

Determining Potential Applications

Once the composition, microstructure, and mechanical properties have been determined, the potential applications of the brass can be assessed. The exact composition and microstructure will dictate its suitability for various applications. For example, brass with a higher zinc content tends to be more ductile, while brass with a lower zinc content is generally stronger. The presence of specific trace elements might affect its corrosion resistance or other properties. These factors will determine whether this particular sample of brass would be suitable for applications such as plumbing fixtures, electrical connectors, musical instruments, or decorative items.

Conclusion: Maximizing Information from a Small Sample

Even a sample of brass weighing only 1.203 grams offers a rich source of information about its composition, microstructure, and mechanical properties. By employing a range of analytical techniques, from XRF and ICP-OES to optical and electron microscopy, we can unlock a wealth of data. This information allows us to understand the material's characteristics and assess its potential applications. This highlights the power of modern analytical techniques in characterizing materials, even when dealing with minuscule sample quantities. The seemingly insignificant 1.203 grams becomes a gateway to a detailed understanding of material science principles and engineering applications. The insights gained extend beyond the individual sample, contributing to broader knowledge about brass alloys and their versatile applications. Further research and testing might reveal even more detail, highlighting the continuous evolution of material characterization techniques and their importance in various scientific and industrial fields. The investigation of this small sample serves as a testament to the meticulous scientific approaches employed in material analysis, and underlines the potential for impactful discoveries, regardless of the scale.

Latest Posts

Latest Posts

-

Change Management And Patient Advocacy Shadow Health

Apr 02, 2025

-

A Good Witness Is Someone Who Is In Their Thoughts

Apr 02, 2025

-

Exercise 13 Review Sheet Art Labeling Activity 2

Apr 02, 2025

-

Interventions Based On Antecedent Manipulations Act Upon The

Apr 02, 2025

-

When Giving Abdominal Thrusts How Should Brianna Position Her Hands

Apr 02, 2025

Related Post

Thank you for visiting our website which covers about A Sample Of Brass Weighing 1.203 Grams . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.