A Tube Is Being Stretched While Maintaining

Onlines

Apr 06, 2025 · 5 min read

Table of Contents

A Tube Being Stretched While Maintaining: Exploring the Physics and Engineering Challenges

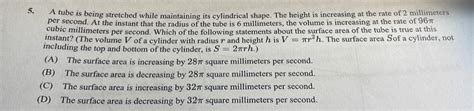

The seemingly simple act of stretching a tube, while maintaining its integrity and properties, unveils a complex interplay of physics and engineering. This process, crucial in various industries from manufacturing flexible electronics to designing robust pipelines, demands a deep understanding of material science, stress analysis, and strain behavior. This article delves into the intricacies of stretching tubes, examining the forces at play, the challenges faced, and the innovative solutions employed to achieve successful and controlled elongation.

Understanding the Forces Involved

Stretching a tube involves applying tensile forces along its longitudinal axis. These forces induce stress within the material, causing it to deform and experience strain. The relationship between stress and strain is dictated by the material's elastic modulus (Young's modulus), a measure of its stiffness. A higher Young's modulus indicates a stiffer material requiring more force to achieve the same elongation.

Tensile Stress and Strain

Tensile stress (σ) is the force (F) per unit area (A) applied to the tube: σ = F/A. As the tube stretches, its length increases, leading to tensile strain (ε), defined as the change in length (ΔL) divided by the original length (L): ε = ΔL/L. For elastic materials, stress and strain are linearly related within the elastic limit, following Hooke's Law: σ = Eε, where E is Young's modulus.

Other Stresses and Considerations

Beyond tensile stress, stretching a tube also generates other stresses:

-

Circumferential Stress: The reduction in the tube's cross-sectional area during stretching induces circumferential stress, tending to reduce the tube's diameter. This stress needs careful consideration, especially for tubes with thin walls, as it can lead to instability and failure.

-

Shear Stress: Depending on the stretching mechanism, shear stresses can also develop, especially at the points of contact between the tube and the stretching device. These stresses can contribute to localized deformations or even fracture.

-

Stress Concentrations: Any imperfections or irregularities on the tube's surface, such as scratches or welds, act as stress concentrators, amplifying the local stress levels and potentially leading to premature failure.

Maintaining Tube Integrity During Stretching

Maintaining a tube's integrity during stretching requires careful control over several parameters:

Material Selection

The choice of material is paramount. Materials with high tensile strength, ductility (ability to deform plastically before fracture), and toughness (ability to absorb energy before failure) are preferred. Common choices include various metals (steel, aluminum, copper), polymers (polypropylene, polyethylene), and composites. The specific material selection depends heavily on the application and the desired properties of the stretched tube.

Stretching Techniques

Various techniques are employed to stretch tubes, each offering advantages and disadvantages:

-

Hydraulic Stretching: This method uses hydraulic pressure to expand the tube's inner diameter, indirectly increasing its length. It's suitable for ductile materials and allows for relatively uniform stretching.

-

Mechanical Stretching: This involves directly pulling the tube using mechanical devices like clamps, rollers, or draw benches. This method offers greater control over the stretching process but might introduce localized stresses.

-

Thermal Stretching: This technique uses heat to soften the material, making it easier to stretch. It is often combined with other methods for enhanced control and uniformity.

Controlled Stretching Rate

The rate at which the tube is stretched significantly impacts its integrity. Too rapid stretching can introduce excessive stress concentrations and lead to fracturing. Controlled, slow stretching allows for stress relaxation and ensures more uniform deformation.

Lubrication

Applying lubricants during the stretching process minimizes friction and reduces shear stresses. This is especially important for mechanical stretching, ensuring smoother deformation and preventing surface damage.

Monitoring and Control

Throughout the stretching process, monitoring key parameters like tensile force, elongation, and temperature is crucial. This data informs the adjustment of stretching parameters in real-time to maintain optimal conditions and prevent failures. Modern techniques employ sensors and feedback systems to achieve precise control.

Advanced Techniques and Challenges

Several advanced techniques and challenges arise when striving for precise and controlled stretching:

Non-Uniform Stretching

Stretching a tube uniformly along its entire length can be challenging. Variations in material properties, imperfections, or uneven force application can lead to non-uniform stretching, causing stress concentrations and weakening the structure. Advanced techniques like pre-straining or using specialized stretching tools help mitigate this issue.

Stretching Tubes with Embedded Components

Stretching tubes with embedded components, such as wires, sensors, or actuators, introduces further challenges. The embedded components must withstand the stresses imposed during stretching without damage or malfunction. Specialized designs and material choices are crucial to ensure compatibility.

Micro- and Nano-scale Stretching

Stretching tubes at the micro- and nano-scale presents unique challenges. Surface effects and quantum mechanical phenomena become significant at these scales, requiring the development of specialized techniques and materials. These techniques are crucial for applications in microelectronics and nanotechnology.

Applications and Industries

The controlled stretching of tubes finds applications across various industries:

Manufacturing

- Flexible Electronics: Stretching techniques are used to create flexible circuits and displays by stretching thin films and substrates.

- Medical Devices: Stretched tubes are used in catheters, stents, and other medical devices requiring flexibility and strength.

- Automotive Industry: Stretching is used to create lightweight and strong components for automobiles, including fuel lines and body panels.

Infrastructure

- Pipelines: The controlled stretching of pipes is crucial in constructing long-distance pipelines, accommodating thermal expansion and ground movement.

- Telecommunications: Stretching techniques are used in the manufacturing of optical fibers and cables.

Aerospace

- Aerospace components: Lightweight and high-strength tubes produced using stretching are crucial in aircraft and spacecraft construction.

Future Directions

Research continues to improve the precision and efficiency of tube stretching techniques. Areas of active research include:

- Development of novel materials: Exploring new materials with enhanced strength, ductility, and flexibility.

- Advanced simulation techniques: Using advanced computational models to predict and optimize the stretching process.

- Automated stretching systems: Developing automated systems for precise control and high-throughput stretching.

Conclusion

Stretching a tube, while maintaining its integrity and desired properties, is a sophisticated process that demands a comprehensive understanding of material science, stress analysis, and engineering design. The choice of materials, stretching techniques, and precise control over parameters are crucial for successful implementation. As technology advances, the ability to precisely control and manipulate the stretching process opens doors to new applications and pushes the boundaries of engineering innovation across various sectors. From flexible electronics to robust infrastructure, the controlled stretching of tubes plays a vital role in shaping the future of technology and manufacturing.

Latest Posts

Latest Posts

-

Quiz 2 1 Conjectures Compounds And Conditionals

Apr 08, 2025

-

The Disagreement Between These Economists Is Most Likely Due To

Apr 08, 2025

-

Landfill Waste Results In Air Pollution As

Apr 08, 2025

-

Catcher In The Rye Ch 17 Summary

Apr 08, 2025

-

After An Insured Gives Notice Of Loss What Must He She

Apr 08, 2025

Related Post

Thank you for visiting our website which covers about A Tube Is Being Stretched While Maintaining . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.