All Of The Following Are True About Hacksaws Except

Onlines

Mar 15, 2025 · 5 min read

Table of Contents

All of the Following are True About Hacksaws Except… Debunking Common Myths

Hacksaws, those ubiquitous hand saws with their fine teeth and adjustable frames, are essential tools in any workshop. But even experienced DIYers might harbor misconceptions about their capabilities and limitations. This comprehensive guide will delve into the common truths about hacksaws, ultimately revealing what statement about them is false. We'll cover everything from blade selection and proper technique to the types of materials hacksaws can (and can't) effectively cut. By the end, you'll be a hacksaw expert, capable of tackling any cutting task with confidence.

Understanding the Hacksaw: A Deep Dive

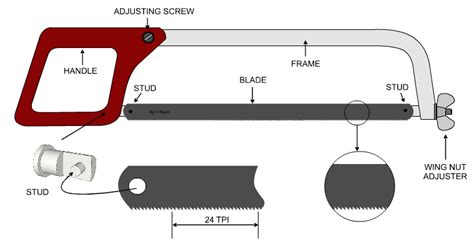

Before we tackle the myths, let's establish a solid foundation. A hacksaw is a hand-operated saw designed for precise cutting of metal and other hard materials. Its defining features include:

- Adjustable Frame: Allows for blade tension adjustment, crucial for preventing blade breakage and ensuring efficient cutting.

- Fine-Tooth Blade: Typically ranging from 14 to 32 teeth per inch (TPI), the fine teeth are designed for controlled cutting of hard materials. Higher TPI blades are for finer cuts, lower TPI for thicker materials.

- Versatile Applications: While primarily used for metal, hacksaws can also cut plastics, wood, and even bone (though specialized blades might be needed).

Key Components & Their Importance

Understanding the different parts of a hacksaw is critical for proper usage and maintenance:

- Frame: Provides stability and tension for the blade. Different frame materials (steel, aluminum) offer varying levels of durability and weight.

- Blade: The heart of the hacksaw, the blade's teeth are responsible for the cutting action. Choosing the correct blade for the material is paramount.

- Handle: Provides grip and leverage during cutting. Ergonomic handles improve comfort and reduce hand fatigue.

- Adjusting Screw/Nut: This component allows for precise tensioning of the blade, a crucial step for preventing breakage and ensuring smooth cutting.

Common Truths About Hacksaws

Let's address some widely accepted facts about hacksaws:

1. Blade Selection is Crucial:

The success of any hacksaw operation hinges on choosing the right blade. Different materials require different TPI (Teeth Per Inch):

- High TPI (24-32 TPI): Ideal for thin-walled tubing, sheet metal, and other delicate materials. The finer teeth produce a smoother, more precise cut.

- Medium TPI (18-24 TPI): A good all-around choice for a variety of materials, offering a balance between cutting speed and precision.

- Low TPI (14-18 TPI): Suitable for thicker materials like solid bar stock and pipes. The larger teeth remove more material with each stroke.

Incorrect blade selection leads to slow cutting, broken blades, and poor-quality cuts.

2. Proper Blade Tension is Essential:

A properly tensioned blade is critical. Too loose, and the blade will wander and produce a ragged cut, potentially breaking. Too tight, and it will snap under pressure. The blade should have a slight bow, but not be excessively taut. Always refer to your hacksaw's instructions for optimal tensioning.

3. Cutting Technique Matters:

Proper technique minimizes the risk of blade breakage and ensures clean cuts. Avoid applying excessive pressure; let the teeth do the work. Use short, controlled strokes with even pressure, maintaining a consistent speed. Pulling the saw back is just as important as pushing.

4. Lubrication Improves Cutting Performance:

Lubricating the blade with cutting fluid (like oil or water-soluble coolant) significantly reduces friction, resulting in smoother cuts, extended blade life, and faster cutting. This is particularly important when cutting hard metals.

5. Hacksaws are Versatile but Have Limitations:

While versatile, hacksaws aren't suitable for all materials or cutting applications. They are not designed for fast, rough cuts. They are most effective on materials with sufficient thickness for the teeth to engage properly. Attempting to cut extremely thick or very hard materials will likely result in a broken blade or inefficient cutting.

Debunking the Myth: What's FALSE About Hacksaws?

Now, let's reveal the statement that is false regarding hacksaws:

False Statement: "Hacksaws can easily and quickly cut through hardened steel with minimal effort."

This statement is demonstrably false. Hardened steel possesses significantly higher tensile strength and hardness than most other materials. While a hacksaw can theoretically cut hardened steel, it would be an extremely slow, laborious process, requiring considerable effort and resulting in a high likelihood of blade breakage. Specialized equipment like abrasive cutoff wheels or bandsaws are far better suited for cutting hardened steel efficiently and safely. Using a hacksaw for such a task is impractical and potentially dangerous.

Advanced Hacksaw Techniques & Troubleshooting

To further solidify your hacksaw expertise, let's explore some advanced techniques and common problems:

1. Starting the Cut:

Use a center punch to create a starting point for the blade. This prevents the blade from wandering and makes it easier to start the cut.

2. Cutting Curves:

While not ideal for tight curves, a hacksaw can be used to cut moderate curves. Use short strokes and guide the saw carefully.

3. Blade Breakage:

Blade breakage is a common issue often stemming from improper tension, applying too much pressure, or using the wrong blade for the material. Always check the blade's tension before each use and select the correct blade for the material being cut.

4. Maintaining Your Hacksaw:

Regular cleaning and lubrication will extend the life of your hacksaw. After each use, wipe the blade clean and store it properly to prevent rust.

Conclusion: Mastering the Hacksaw

The hacksaw, despite its seemingly simple design, is a powerful and versatile tool when used correctly. Understanding its capabilities, limitations, and proper techniques allows for efficient and safe cutting of a variety of materials. Remember, the key to successful hacksaw usage lies in proper blade selection, correct tensioning, and a smooth, controlled cutting action. By avoiding the misconception that hacksaws are ideal for hardened steel and embracing the truths outlined above, you can confidently add this essential tool to your arsenal of workshop essentials. Now that you've debunked the myth and gained a deeper understanding of hacksaws, you're ready to tackle any cutting project with precision and confidence.

Latest Posts

Latest Posts

-

In Which Culture Is A Person Who Sees Him Herself

Mar 15, 2025

-

Summary Of A Feast For Crows

Mar 15, 2025

-

Jaime Decidir Comprar Tableta

Mar 15, 2025

-

You Respond To A Movie Theater For A 70

Mar 15, 2025

-

Po Box 15284 Wilmington De 19850

Mar 15, 2025

Related Post

Thank you for visiting our website which covers about All Of The Following Are True About Hacksaws Except . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.