Avoid __________ While Working In The Mechanics Laboratory.

Onlines

Mar 06, 2025 · 6 min read

Table of Contents

Avoid These Hazards While Working in the Mechanics Laboratory

The mechanics laboratory is a dynamic environment brimming with opportunities for learning and experimentation. However, this environment also presents significant safety hazards if proper precautions aren't taken. Ignoring safety protocols can lead to serious injuries, equipment damage, and disruptions to the learning process. This comprehensive guide outlines crucial safety measures and hazards to avoid while working in a mechanics laboratory. Understanding and adhering to these guidelines is paramount for a safe and productive laboratory experience.

Understanding the Mechanics Lab Environment: A Potential Minefield of Hazards

A typical mechanics lab contains a variety of tools, equipment, and materials, each with its own set of potential risks. These include:

1. Machinery and Equipment Hazards:

- Rotating Equipment: Lathes, milling machines, drills, and other rotating machinery pose significant risks of entanglement, crushing, and cutting injuries. Never reach into moving machinery or attempt to adjust settings while it's operating. Always ensure that safety guards are in place and functioning correctly.

- Hydraulic and Pneumatic Systems: High-pressure systems can cause serious injuries if not handled properly. Always follow established procedures for operating and maintaining these systems. Be aware of potential leaks and take appropriate preventative measures.

- Power Tools: Handheld power tools like grinders, saws, and impact wrenches require careful handling. Ensure that tools are in good working order, properly maintained, and used with appropriate safety gear. Never operate a power tool without proper training.

- Lifting Equipment: Cranes, hoists, and other lifting equipment must be used correctly and only by trained personnel. Improper use can result in serious injury or death. Always follow the manufacturer's instructions and safety guidelines.

2. Material Hazards:

- Sharp Objects: Metal shavings, broken tools, and sharp edges on equipment can cause cuts and lacerations. Always wear appropriate personal protective equipment (PPE), including gloves and safety glasses. Handle materials carefully and dispose of sharp objects properly.

- Hot Surfaces: Many machines generate heat during operation. Always allow sufficient time for equipment to cool before handling. Use appropriate heat-resistant gloves when necessary.

- Chemicals: Some mechanics labs use chemicals for cleaning, lubrication, or other purposes. Always handle chemicals according to the manufacturer's safety data sheets (SDS). Ensure adequate ventilation and wear appropriate PPE.

- Dust and Particles: Metalworking can generate significant amounts of dust and particles that can be inhaled or cause skin irritation. Use appropriate respiratory protection and eye protection to minimize exposure.

3. Environmental Hazards:

- Noise: The mechanics lab can be a noisy environment. Prolonged exposure to loud noises can cause hearing damage. Always wear hearing protection when operating noisy equipment.

- Lighting: Ensure that the workspace is adequately lit to prevent accidents. Poor lighting can lead to eye strain and increase the risk of injury.

- Clutter: A cluttered workspace increases the risk of tripping, falling, and other accidents. Keep the work area clean and organized at all times.

- Fire Hazards: Flammable materials and electrical equipment increase the risk of fire. Always have a fire extinguisher readily available and know how to use it. Follow proper procedures for handling flammable materials.

Implementing Essential Safety Measures: Your Shield Against Accidents

Beyond avoiding specific hazards, proactive safety measures are crucial for minimizing risks within the mechanics lab.

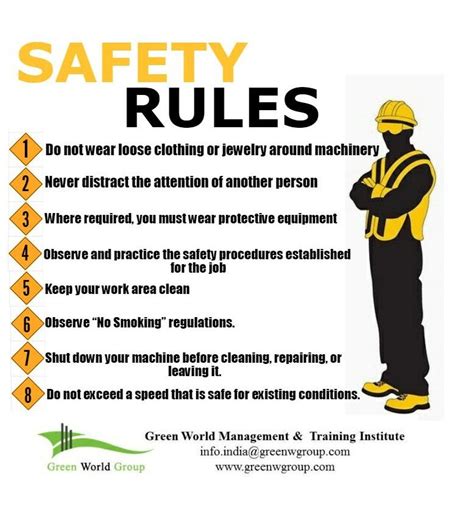

1. Personal Protective Equipment (PPE): Your First Line of Defense

Proper PPE is non-negotiable in the mechanics lab. This includes:

- Safety Glasses: Always wear safety glasses to protect your eyes from flying debris, sparks, and chemical splashes.

- Hearing Protection: Use earplugs or earmuffs to protect your hearing from excessive noise.

- Gloves: Wear appropriate gloves to protect your hands from cuts, abrasions, chemicals, and heat.

- Safety Shoes: Steel-toe safety shoes are essential to protect your feet from falling objects and crushing hazards.

- Respirator: Use a respirator when working with dust, fumes, or chemicals.

- Lab Coat: A lab coat protects your clothing and skin from spills and splashes.

2. Proper Training and Supervision: Knowledge is Power

Never attempt to use equipment or perform tasks without proper training. Always seek guidance from experienced personnel or instructors. Understand the operating procedures for all equipment before using it. Supervision is especially important for beginners.

3. Machine Maintenance and Inspection: Preventing Catastrophic Failures

Regular maintenance and inspection of equipment are vital for preventing accidents. Report any damaged or malfunctioning equipment immediately. Never use equipment that is not in good working order. Follow established maintenance schedules diligently.

4. Emergency Procedures: Preparedness is Key

Familiarize yourself with the emergency procedures in the mechanics lab. Know the location of fire extinguishers, first-aid kits, and emergency exits. Understand how to respond to different types of emergencies, such as fires, chemical spills, or injuries. Participate actively in fire drills and other safety training exercises.

5. Housekeeping and Organization: A Tidy Space, A Safer Space

Maintain a clean and organized workspace. Remove unnecessary items from the work area. Dispose of waste materials properly. Proper housekeeping reduces the risk of tripping, falling, and other accidents. Clean up spills immediately.

Specific Hazards to Avoid: A Detailed Breakdown

Let's delve deeper into some specific hazards and how to mitigate them.

1. Avoiding Entanglement Hazards:

Long hair, loose clothing, and jewelry can easily become entangled in rotating machinery. Always tie back long hair, wear close-fitting clothing, and remove jewelry before operating any machinery. Never wear scarves or loose-fitting garments near moving parts.

2. Preventing Cuts and Lacerations:

Handle sharp objects carefully. Use appropriate cutting tools and techniques. Dispose of sharp objects properly in designated containers. Never attempt to catch a falling sharp object with your hands. Inspect tools for damage before use.

3. Minimizing Chemical Exposure:

Always read and follow the SDS for any chemicals used in the lab. Wear appropriate PPE, including gloves, eye protection, and respiratory protection. Work in a well-ventilated area. Dispose of chemicals properly according to regulations. Never mix chemicals unless explicitly instructed to do so.

4. Safe Handling of Compressed Air:

Never point a compressed air hose at yourself or others. The high-velocity air can cause serious injury to eyes or skin. Use compressed air only for its intended purpose. Ensure that the air hose is securely connected and in good working condition.

5. Preventing Electrical Hazards:

Never work with electrical equipment if you are not properly trained. Ensure that all electrical equipment is properly grounded. Never work on energized equipment. Report any damaged or faulty electrical equipment immediately. Always use insulated tools when working with electricity.

Beyond the Lab: Extending Safety Practices

The principles of safety learned in the mechanics lab extend far beyond its walls. The habits you develop regarding personal protective equipment, cautious tool handling, and hazard awareness are transferable to any environment involving machinery, tools, or potentially hazardous materials. This consistent approach to safety promotes a culture of responsibility and dramatically reduces the likelihood of injury, not just in the lab, but also in everyday life.

Conclusion: Safety First, Always

Working in a mechanics laboratory requires a proactive and conscientious approach to safety. By understanding the potential hazards, implementing appropriate safety measures, and adhering to established procedures, you can significantly reduce the risk of accidents and create a safer learning and working environment for yourself and others. Remember, safety is not just a set of rules; it's a mindset—a commitment to prioritizing well-being above all else. Embrace this commitment, and your time in the mechanics lab will be both productive and safe.

Latest Posts

Latest Posts

-

Before Replacing Parts Such As Bits Blades

Mar 06, 2025

-

The Bell Jar Summary Chapter By Chapter

Mar 06, 2025

-

The Political Capital Of The Northern Tribes Was At

Mar 06, 2025

-

The Immortal Life Of Henrietta Lacks Summary By Chapter

Mar 06, 2025

-

Hilda Just Got Her First Sales Position

Mar 06, 2025

Related Post

Thank you for visiting our website which covers about Avoid __________ While Working In The Mechanics Laboratory. . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.