Ball Joints In Reciprocating Engine Exhaust Systems Should Be

Onlines

Mar 21, 2025 · 5 min read

Table of Contents

Ball Joints in Reciprocating Engine Exhaust Systems: Should They Be Used?

The design of an exhaust system for a reciprocating engine is a crucial aspect of overall vehicle performance and longevity. It’s responsible for safely and efficiently channeling hot, noxious gases away from the engine while minimizing noise and maximizing power output. Within this intricate system, the choice of connection points and their articulation is vital. This article delves into the merits and drawbacks of using ball joints in reciprocating engine exhaust systems, a relatively uncommon but increasingly considered design element.

Understanding the Challenges of Exhaust System Design

Before diving into the specifics of ball joints, let's outline the core challenges inherent in reciprocating engine exhaust system design:

1. Thermal Expansion and Contraction:

Exhaust systems operate under extreme temperature conditions, experiencing significant thermal expansion during operation and contraction during cool-down. This fluctuation can lead to stress on the system components, potentially causing leaks, cracks, or premature failure if not properly addressed.

2. Vibration and Engine Movement:

Reciprocating engines, by their nature, produce vibrations that transmit through the engine mounts and chassis. These vibrations, coupled with engine movement (especially in vehicles with significant suspension articulation), exert forces on the exhaust system, demanding resilient and flexible connections.

3. Corrosion:

Exposure to high temperatures, moisture, and corrosive exhaust gases accelerates corrosion in exhaust components. Materials selection and design are critical to mitigate this issue and ensure long-term system integrity.

4. Noise Reduction:

Excessive noise emanating from the exhaust system is undesirable. Effective design necessitates minimizing noise propagation through careful selection of materials, component geometry, and connection methods.

5. Back Pressure:

Excessive back pressure hinders engine performance, impacting efficiency and power output. The exhaust system's design must minimize back pressure while effectively removing exhaust gases.

The Case for Ball Joints in Exhaust Systems

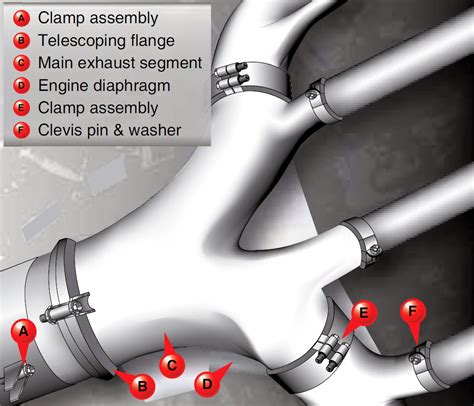

Traditional exhaust system designs often rely on rigid connections or flexible components like bellows or corrugated pipes. However, ball joints offer a unique set of advantages:

1. Enhanced Flexibility and Articulation:

Ball joints allow for multi-directional movement, absorbing vibrations and engine movements far more effectively than rigid connections. This flexibility is especially beneficial in applications with significant suspension travel, such as off-road vehicles or heavy-duty trucks. The reduced stress on the exhaust system components translates to a longer lifespan and reduced risk of failure.

2. Improved Stress Distribution:

By accommodating movement, ball joints distribute stress more evenly across the system, minimizing localized stress points that could lead to cracking or fatigue failure. This is crucial for ensuring the system’s durability, particularly in high-vibration environments.

3. Reduced Noise Transmission:

The flexibility offered by ball joints can contribute to reduced noise transmission. By absorbing vibrations, they can dampen the propagation of noise through the exhaust system and into the vehicle cabin. While not a primary noise reduction mechanism, it's a valuable supplementary benefit.

4. Simplified Installation and Maintenance:

In some configurations, ball joints can simplify installation and maintenance. Their flexibility allows for easier alignment and connection of exhaust components, potentially reducing installation time and labor costs. Moreover, access to individual components for maintenance or repair may be easier with a ball joint system.

The Counterarguments Against Ball Joints in Exhaust Systems

While ball joints present compelling advantages, there are also potential drawbacks to consider:

1. Higher Cost and Complexity:

Ball joints are generally more expensive than traditional connection methods like flanges and clamps. Their design and manufacturing are more complex, resulting in a higher initial cost. Furthermore, the additional components involved can increase the overall system complexity.

2. Potential for Leaks:

Proper sealing of a ball joint is critical to prevent exhaust leaks. A poorly designed or improperly installed ball joint can lead to leaks, resulting in exhaust gas emissions and potential safety hazards. Careful attention to sealing and material selection is essential.

3. Limited Temperature Resistance:

The materials used in ball joints must withstand the high temperatures of the exhaust system. While high-temperature materials are available, they can be more expensive and may have limitations in terms of flexibility or durability compared to lower-temperature alternatives. Careful material selection is paramount.

4. Wear and Tear:

Ball joints are mechanical components subject to wear and tear over time. The constant movement and exposure to high temperatures and corrosive gases can accelerate wear, potentially requiring periodic maintenance or replacement. The design should account for this potential wear, aiming for durability and ease of replacement.

5. Weight Considerations:

Depending on the design and material choice, ball joints can add weight to the exhaust system. While the added weight may be insignificant in many applications, it should be considered, especially in situations where weight minimization is a critical design constraint.

Applications and Material Considerations

The suitability of ball joints in an exhaust system heavily relies on the specific application. High-vibration or high-articulation applications, such as off-road vehicles or heavy-duty machinery, are where ball joints demonstrate their greatest value. Passenger cars, on the other hand, may find the added cost and complexity less justifiable.

Material selection plays a critical role in determining the ball joint’s performance and lifespan. High-temperature alloys, such as stainless steel or Inconel, are often preferred for their resistance to corrosion and heat degradation. Proper sealing mechanisms, possibly incorporating high-temperature gaskets or seals, are also crucial for preventing leaks.

Conclusion: A Balanced Perspective

The question of whether ball joints should be used in reciprocating engine exhaust systems doesn't have a simple yes or no answer. The decision depends on a careful weighing of the advantages and disadvantages in the context of the specific application. The enhanced flexibility, stress distribution, and potential noise reduction offered by ball joints make them a compelling option for applications demanding high articulation and durability. However, the increased cost, potential for leaks, and maintenance considerations must be carefully evaluated. For applications where these drawbacks outweigh the advantages, traditional connection methods may remain the more suitable choice. A thorough analysis of the operational environment, cost constraints, and desired lifespan of the exhaust system is essential for making an informed decision. Future research and development might focus on improving the durability, cost-effectiveness, and sealing mechanisms of ball joints for wider adoption in reciprocating engine exhaust systems.

Latest Posts

Latest Posts

-

Amoeba Sisters Video Recap Classification Answer Sheet

Mar 27, 2025

-

5 1 Models Of The Atom Answer Key

Mar 27, 2025

-

The Wretched And The Beautiful Pdf

Mar 27, 2025

-

4 07 Putting Your Work Out There

Mar 27, 2025

-

La Doctora Salazar Me Recomienda Un De Pies A Cabeza

Mar 27, 2025

Related Post

Thank you for visiting our website which covers about Ball Joints In Reciprocating Engine Exhaust Systems Should Be . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.