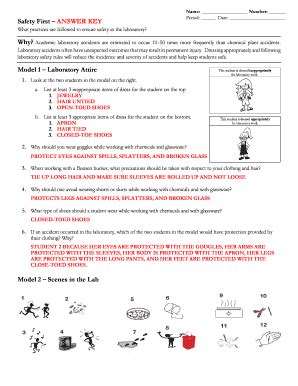

Model 2 Scenes In The Lab

Onlines

Mar 04, 2025 · 6 min read

Table of Contents

Modeling 2 Scenes in the Lab: A Comprehensive Guide for Researchers and Students

The ability to accurately model scenes within a laboratory setting is crucial for a wide range of scientific disciplines. From physics and engineering to biology and chemistry, understanding how to create realistic and reproducible scenarios is essential for conducting meaningful experiments and drawing valid conclusions. This comprehensive guide delves into the intricacies of modeling two distinct scenes within a controlled lab environment, covering various aspects from experimental design to data analysis.

Scene 1: Fluid Dynamics in a Microfluidic Device

This section focuses on modeling fluid flow within a microfluidic device, a common tool in numerous scientific fields. Microfluidics involves manipulating and controlling fluids at the microscale, allowing for precise control over fluid behavior and interaction. Modeling these systems is crucial for optimizing device design and predicting experimental outcomes.

Defining the Problem: Laminar vs. Turbulent Flow

The first step in modeling a microfluidic scene is clearly defining the fluid dynamics involved. Microfluidic devices typically operate under laminar flow conditions, characterized by smooth, layered fluid movement. However, under certain conditions, turbulent flow can occur, characterized by chaotic and unpredictable fluid motion. The Reynolds number (Re), a dimensionless quantity, helps determine the flow regime:

- Low Re (Re << 2300): Laminar flow, suitable for many microfluidic applications.

- High Re (Re >> 4000): Turbulent flow, requiring more complex modeling techniques.

Accurate modeling necessitates identifying the relevant Re for the specific microfluidic device and experimental conditions.

Modeling Approaches: Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics (CFD) is a powerful tool for simulating fluid flow in complex geometries, like microfluidic devices. CFD involves solving the Navier-Stokes equations, which govern fluid motion, using numerical methods. Popular software packages include ANSYS Fluent, COMSOL Multiphysics, and OpenFOAM.

Steps involved in CFD modeling:

- Geometry Creation: Constructing a precise 3D model of the microfluidic device using CAD software.

- Mesh Generation: Dividing the geometry into a mesh of smaller elements for numerical computation. Mesh refinement is crucial for accuracy, particularly in regions with high flow gradients.

- Boundary Condition Definition: Specifying the inflow and outflow conditions, as well as wall boundary conditions (no-slip or slip). This is crucial for accurately reflecting the experimental setup.

- Solver Selection: Choosing an appropriate solver based on the flow regime and desired accuracy. Different solvers employ different numerical methods and algorithms.

- Simulation and Post-processing: Running the simulation and analyzing the results using visualization tools. This allows for the extraction of key parameters like velocity profiles, pressure distributions, and shear stress.

Validation and Verification: Experimental Comparison

A crucial step in any modeling exercise is validation and verification. This involves comparing the model predictions with experimental data. Discrepancies between the model and experimental results highlight potential errors in the model assumptions, mesh quality, or boundary conditions. Iterative refinement of the model is necessary to achieve good agreement with experimental data.

Scene 2: Chemical Reaction Kinetics in a Stirred Tank Reactor (STR)

This section focuses on modeling chemical reaction kinetics within a stirred tank reactor (STR), a common piece of equipment in chemical engineering and process chemistry. STRs provide excellent mixing, ensuring uniformity in reactant concentrations and temperature. Modeling these systems helps optimize reaction conditions and predict product yields.

Reaction Mechanisms and Rate Laws

Before modeling, a thorough understanding of the reaction mechanism and rate laws is essential. This involves identifying the individual steps in the reaction, their respective rate constants, and the overall reaction order. For complex reactions, detailed kinetic models may be required, considering activation energies, reaction intermediates, and equilibrium constants.

Modeling Approaches: Ordinary Differential Equations (ODEs)

The dynamics of chemical reactions in an STR can be described by a system of ordinary differential equations (ODEs). These equations represent the rate of change of reactant and product concentrations with respect to time. The ODEs are often coupled, meaning that the rate of change of one species depends on the concentration of others.

Developing the ODE system:

- Mass Balance: Applying the principle of mass conservation to each species involved in the reaction.

- Rate Law Incorporation: Substituting the appropriate rate laws into the mass balance equations.

- Parameter Estimation: Determining the values of rate constants and other kinetic parameters through experimentation or literature review.

Numerical Solution Techniques: Solving the ODEs

Solving the ODE system typically requires numerical methods, as analytical solutions are often unavailable for complex reactions. Common numerical techniques include:

- Euler Method: A simple first-order method, suitable for some cases.

- Runge-Kutta Methods: Higher-order methods that offer improved accuracy.

- Software Packages: MATLAB, Python (with libraries like SciPy), and other software packages provide tools for solving ODEs.

Sensitivity Analysis and Parameter Estimation

Once the model is developed, sensitivity analysis is crucial. This involves investigating how changes in model parameters affect the predicted outcomes. This information is invaluable for identifying the most critical parameters and refining the experimental design. Parameter estimation techniques, like least-squares regression, can be used to optimize the model parameters based on experimental data.

Integrating the Two Scenes: Coupled Systems

Many real-world scenarios involve coupling between different physical and chemical processes. For instance, a microfluidic device might be used to control the flow of reactants into an STR, impacting reaction kinetics. Modeling such coupled systems requires integrating the techniques discussed above.

Coupling Fluid Dynamics and Reaction Kinetics

In a coupled system, the fluid flow field influences reactant mixing and transport, directly affecting the reaction rates. This coupling can be modeled using a multiphysics approach, where CFD simulations are linked to the ODE system governing reaction kinetics. Software packages like COMSOL Multiphysics allow for such coupled simulations.

Challenges and Considerations

Modeling coupled systems presents significant challenges:

- Computational Cost: Simulating coupled systems can be computationally expensive, requiring significant computing resources.

- Model Complexity: The complexity of the model increases, making validation and verification more challenging.

- Data Availability: Accurate experimental data is crucial for model validation and parameter estimation.

Conclusion: The Power and Limitations of Modeling

Modeling scenes in the lab, whether focusing on fluid dynamics or reaction kinetics, provides invaluable insights into complex systems. By carefully designing experiments, applying appropriate modeling techniques, and rigorously validating the models, researchers can gain a deeper understanding of the underlying phenomena and optimize experimental conditions. However, it's crucial to acknowledge the limitations of modeling: models are simplifications of reality, and their accuracy depends heavily on the underlying assumptions and the quality of experimental data. Continuous refinement and validation are essential for ensuring the reliability and usefulness of lab-based models. Furthermore, integrating different modeling approaches allows for a more holistic understanding of coupled systems, leading to more accurate predictions and optimized designs. The ability to effectively model two or more scenes within the lab significantly enhances research capabilities, facilitating advancements across various scientific and engineering disciplines. The future of scientific research hinges on the continued development and application of sophisticated modeling techniques to address increasingly complex experimental scenarios.

Latest Posts

Latest Posts

-

Where The Red Fern Grows Quotes

Mar 04, 2025

-

Drag The Appropriate Labels To Their Respective Targets Resethelp

Mar 04, 2025

-

Body Ritual Among The Nacirema Summary

Mar 04, 2025

-

Which Of The Following Statements About Savings Accounts Is False

Mar 04, 2025

-

What Formula Would Produce The Value In Cell C25

Mar 04, 2025

Related Post

Thank you for visiting our website which covers about Model 2 Scenes In The Lab . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.