Offset Lithography Is A Form Of Intaglio Printing.

Onlines

Apr 01, 2025 · 5 min read

Table of Contents

Offset Lithography: Dispelling the Intaglio Myth

The statement "Offset lithography is a form of intaglio printing" is fundamentally incorrect. Offset lithography and intaglio printing are distinct and contrasting printing techniques, relying on entirely different principles for transferring ink to the substrate (paper, canvas, etc.). While both are significant in the history of printmaking and graphic arts, conflating them demonstrates a misunderstanding of their core mechanisms. This article will delve deep into the specifics of each process, highlighting their differences to definitively clarify their separate identities.

Understanding Lithography: The Planographic Process

Lithography, from the Greek words "lithos" (stone) and "graphein" (to write), initially used a flat printing surface – a planographic process. Unlike intaglio, which utilizes recessed areas to hold ink, or relief printing (like letterpress) which uses raised surfaces, lithography leverages the principle of oil and water repulsion. A special lithographic stone (or modern metal plate) is treated to accept both water and oil-based ink.

The Lithographic Process: A Step-by-Step Guide

-

Image Creation: The image is drawn or created on the lithographic plate using a greasy substance (like lithographic crayon or tusche). This creates the areas that will ultimately hold the ink.

-

Treatment: The plate is then treated with a chemical solution that makes the image-bearing areas receptive to oil-based ink and the non-image areas receptive to water.

-

Inking and Dampening: In the printing press, rollers apply a thin layer of water to the entire plate. This water adheres to the non-image areas. Subsequently, oil-based ink is applied, only adhering to the greasy image areas due to the principle of oil and water repulsion.

-

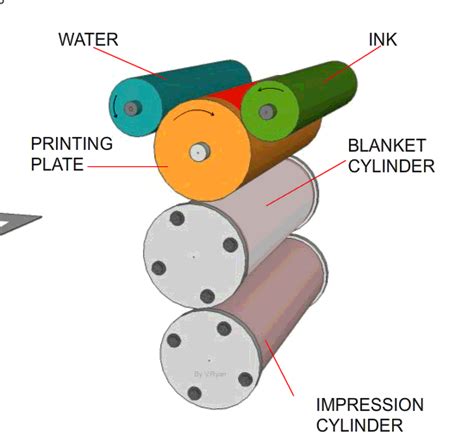

Transfer: This inked image is then transferred to a rubber blanket cylinder (offsetting the image), which finally presses the image onto the paper. This offsetting stage is crucial to offset lithography and is the reason for its name. The blanket cylinder acts as an intermediary, ensuring even ink distribution and preventing the plate from wearing down.

Offset Lithography: Mass Production Made Possible

Offset lithography's ingenious use of the offset blanket cylinder made it uniquely suited for mass production. The rubber blanket's resilience enables thousands of impressions without degrading the image quality on the master plate. This characteristic revolutionized commercial printing, allowing for the cost-effective creation of books, magazines, newspapers, and marketing materials on a large scale. This is a critical distinction from the more labor-intensive processes associated with intaglio.

Intaglio Printing: The World of Recessed Images

Intaglio, meaning "to cut into," is a printing method where the ink sits within incised lines or areas on a printing plate. The process involves creating grooves or pits in a metal plate (typically copper, zinc, or steel), which then retain the ink.

Different Intaglio Techniques:

Several techniques fall under the umbrella of intaglio printing, each with its unique approach to creating the recessed areas:

-

Engraving: The artist uses a burin (a sharp, V-shaped tool) to directly carve the image into the metal plate. This requires immense skill and precision.

-

Etching: The plate is covered with a protective ground, and the image is drawn or scratched into the ground, exposing the metal underneath. The plate is then submerged in acid, which etches the exposed areas, creating the recessed lines.

-

Drypoint: The artist uses a needle to directly scratch lines into the plate. The burr (raised edge) created by this process gives the print a characteristically soft, velvety texture.

-

Mezzotint: This technique uses a rocker to create a finely textured surface of tiny pits across the plate. The artist then selectively smooths areas to control the tone and create the image.

-

Aquatint: This method employs resin dust to create a granular texture, allowing for tonal variations and subtle gradations in the print.

The Intaglio Printing Process:

-

Inking: The incised lines or pits are filled with ink using a roller or dabber.

-

Wiping: Excess ink is carefully wiped away from the surface of the plate, leaving ink only in the recessed areas. The wiping technique is crucial to controlling the final print's appearance, with various methods resulting in different effects.

-

Pressing: The inked plate is pressed against the paper under significant pressure. This pressure forces the paper into the recessed areas, transferring the ink to the paper and creating the print.

Key Differences: Lithography vs. Intaglio

The fundamental difference lies in the nature of the printing surface. Lithography uses a flat, planographic surface, relying on the principle of oil and water repulsion, while intaglio uses a recessed surface, with ink residing within the grooves. This distinction leads to significant differences in the printing process, the resulting image quality, and the applications of each technique.

| Feature | Lithography | Intaglio |

|---|---|---|

| Surface | Planographic (flat) | Intaglio (recessed) |

| Ink Location | On the surface of the raised image areas | Within the recessed lines or pits |

| Principle | Oil and water repulsion | Ink trapped in recesses, pressure transfer |

| Pressure | Relatively low | Relatively high |

| Mass Production | Highly suitable | Less suitable, often limited editions |

| Image Quality | Crisp lines and flat tones | Rich blacks, velvety textures, tonal depth |

| Ink Type | Oil-based | Oil-based |

Conclusion: Separate But Equal

Offset lithography and intaglio printing are both significant and powerful printmaking techniques. However, they operate under entirely different principles and produce dramatically different results. Offset lithography's flat, planographic surface and its utilization of oil and water repulsion set it apart from intaglio's reliance on recessed areas and the pressure transfer of ink. The claim that offset lithography is a form of intaglio printing is inaccurate and highlights a fundamental misunderstanding of the core concepts of these distinct and remarkable printing methods. Each technique has its unique strengths, making it suitable for different artistic and commercial applications, both continuing to hold their own place in the world of graphic arts. Understanding these differences is crucial for anyone seeking to appreciate the breadth and complexity of printmaking.

Latest Posts

Latest Posts

-

List All Of The Rumors Told About Gatsby

Apr 02, 2025

-

As I Lay Dying Book Characters

Apr 02, 2025

-

The Cost Of Credit Multimedia Presentation

Apr 02, 2025

-

Activity 3 1 1 Blood Detectives Answer Key

Apr 02, 2025

-

Escoge La Opcion Que Mejor Resume El Cortometraje

Apr 02, 2025

Related Post

Thank you for visiting our website which covers about Offset Lithography Is A Form Of Intaglio Printing. . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.