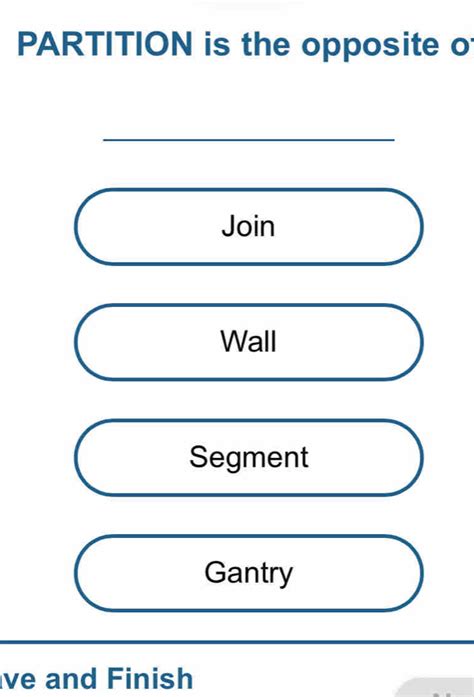

Partition Is The Opposite Of Join Wall Segment Gantry

Onlines

Mar 25, 2025 · 5 min read

Table of Contents

Partition: The Inverse of Joining Wall Segments with Gantry Systems

Partitioning, in the context of construction and industrial processes, represents the exact opposite of joining wall segments using a gantry system. While gantry systems facilitate the precise and efficient joining of large components, partitioning involves the controlled separation or division of a structure or material. Understanding this fundamental difference is crucial for selecting the appropriate methodology and equipment for any given project. This article delves into the contrasting nature of these processes, exploring their applications, associated technologies, and underlying principles.

Understanding Gantry Systems and their Role in Joining

Gantry systems are sophisticated, heavy-duty structures employed for lifting, moving, and assembling large components. They're essentially overhead cranes with a horizontal beam supported by two vertical columns, capable of traversing along a track system. This configuration allows for precise positioning and maneuvering of heavy loads, making them invaluable in applications requiring the joining of large wall segments or prefabricated structural elements.

Key Features of Gantry Systems in Joining Applications:

- High Load Capacity: Gantry cranes boast impressive lifting capacities, easily managing the weight of large wall sections, particularly in industrial and construction settings.

- Precision Movement: The controlled movement of the gantry system ensures accurate alignment during the joining process, minimizing errors and potential damage.

- Versatility: Gantry systems can be customized for various applications and adapted to accommodate different joining techniques.

- Improved Safety: By automating the lifting and positioning of heavy components, gantry systems significantly enhance workplace safety and reduce the risk of human error.

- Increased Efficiency: Gantry systems streamline the joining process, resulting in shorter project timelines and reduced labor costs.

Joining Techniques Employed with Gantry Systems:

The specific joining techniques used in conjunction with gantry systems vary depending on the material and design of the wall segments. Common methods include:

- Welding: Gantry systems accurately position the segments for robust and permanent welding joints.

- Bolting: For structures requiring disassemblability, gantry systems precisely align components for secure bolting.

- Adhesive Bonding: In some cases, gantry systems aid in the precise application of adhesives for joining wall segments.

Partitioning: The Counterpart to Joining

Partitioning, in contrast to joining, involves the controlled separation or division of a structure or material. This process can range from simple wall demarcations in interior spaces to complex demolition and separation of large-scale industrial structures. While seemingly straightforward, partitioning requires careful planning and execution to avoid structural damage and ensure worker safety.

Key Aspects of Partitioning:

- Precise Cutting and Separation: Partitioning frequently involves precise cutting techniques to achieve clean separation without compromising structural integrity.

- Material Handling: Depending on the material and size of the partition, specialized equipment may be needed for safe and efficient material handling.

- Waste Management: Partitioning often generates considerable waste, requiring appropriate disposal or recycling strategies.

- Safety Precautions: Demolition and separation processes necessitate stringent safety protocols to protect workers from potential hazards.

- Structural Integrity: The partitioning method must be chosen to preserve the structural integrity of the remaining sections.

Partitioning Techniques and Applications:

A variety of techniques are employed for partitioning, depending on the material and the desired outcome:

- Demolition: This involves the complete dismantling of a structure, often employed in building renovations or deconstruction projects. Specialized demolition tools and equipment are used to safely remove sections of walls or entire structures.

- Drywall Partitioning: Common in interior construction, this process involves installing drywall partitions to create separate rooms or areas within a building.

- Metal Stud Partitioning: Metal studs form the framework for interior partitions, providing a robust and fire-resistant barrier.

- Glass Partitioning: Used for creating visually appealing and modern interior spaces, glass partitions offer flexibility and transparency.

- Modular Partitioning: Prefabricated modular partitions provide a quick and efficient way to create temporary or permanent divisions within a space.

The Fundamental Differences: Joining vs. Partitioning

The fundamental difference between joining and partitioning lies in their opposing natures. Joining aims to create a unified structure, while partitioning seeks to divide or separate one. This difference translates to contrasting methodologies, equipment requirements, and safety considerations.

| Feature | Joining (Gantry System) | Partitioning |

|---|---|---|

| Objective | Unite wall segments | Separate or divide a structure |

| Process | Precise alignment and connection of components | Controlled cutting, demolition, or separation |

| Equipment | Gantry crane, welding equipment, bolting tools | Demolition tools, cutting tools, partition systems |

| Outcome | Unified and structurally integrated wall segment | Separate sections or rooms |

| Safety Focus | Preventing component slippage and worker injury | Preventing structural collapse and worker injury |

Advanced Considerations and Technological Advancements

Both joining and partitioning benefit from technological advancements. In joining, advancements in robotic automation and sensor technology lead to more precise and efficient assembly. Gantry systems are increasingly integrated with sophisticated control systems for enhanced precision and safety.

In partitioning, advancements in laser cutting and water jet cutting allow for cleaner, more precise cuts in various materials, minimizing waste and maximizing structural integrity. Robotics also play a role in automating demolition tasks, improving safety and efficiency.

Conclusion: A Complementary Dynamic

While seemingly opposite processes, joining and partitioning are integral components of the construction and industrial landscapes. The selection of the appropriate process depends on the project objectives, material properties, and desired outcome. Understanding the key differences, associated technologies, and safety implications of each process is crucial for successful project execution. The efficient and safe execution of both joining and partitioning contributes to the creation of functional, safe, and aesthetically pleasing structures. Their complementary nature ensures the adaptability and evolution of construction techniques in various industrial and building applications. As technology continues to advance, expect further innovations to enhance the precision, efficiency, and safety of both joining and partitioning processes.

Latest Posts

Latest Posts

-

How Is Emphasis Shown In This Image

Mar 28, 2025

-

Skills Module 3 0 Iv Therapy And Peripheral Access Pretest

Mar 28, 2025

-

Summary Of We By Yevgeny Zamyatin

Mar 28, 2025

-

A Mi 1 Of 1 Los Platos

Mar 28, 2025

-

3 07 Quiz Developing A Wellness Approach To Body Size

Mar 28, 2025

Related Post

Thank you for visiting our website which covers about Partition Is The Opposite Of Join Wall Segment Gantry . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.