The Operating Principle Of Float-type Carburetors Is Based On The

Onlines

Mar 31, 2025 · 7 min read

Table of Contents

The Operating Principle of Float-Type Carburetors is Based on the Precise Metering of Fuel and Air

The internal combustion engine, a marvel of engineering, relies on a precise mixture of fuel and air for efficient combustion. In older vehicles, before the advent of fuel injection, this crucial task was handled by the carburetor. Among the various types, the float-type carburetor stands out for its elegant simplicity and effectiveness in delivering a consistent fuel-air mixture. This article delves deep into the operating principle of float-type carburetors, explaining its components, their functions, and the intricate interplay that ensures proper engine operation.

Understanding the Fundamental Principle: Maintaining a Constant Fuel Level

At the heart of the float-type carburetor lies a simple yet ingenious mechanism: maintaining a constant fuel level within the float bowl. This constant level is critical because it provides a consistent fuel supply, regardless of engine speed or load. The mechanism achieving this is based on the interaction between a float, a needle valve, and the fuel supply.

The Float: The Level Sensor

The float, typically a hollow, buoyant chamber, rests on the surface of the fuel within the float bowl. As the fuel level in the bowl rises, the float rises with it. Conversely, as the fuel level drops, the float descends. This simple movement is the key to regulating the fuel supply.

The Needle Valve: The Fuel Gatekeeper

Connected to the float is the needle valve. This valve acts as a gate, controlling the flow of fuel from the fuel supply line into the float bowl. When the fuel level is high and the float is elevated, the needle valve is closed, preventing further fuel entry. As the fuel level drops and the float descends, the needle valve opens, allowing more fuel to flow into the bowl until the desired level is reached. This creates a negative feedback loop: a higher fuel level causes the valve to close, and a lower fuel level causes it to open. This self-regulating system ensures a stable fuel level within the float bowl.

The Fuel Inlet and the Float Bowl: Fuel Storage and Regulation

The fuel inlet is the point at which fuel enters the float bowl. This is usually a connection to the fuel tank via a fuel line. The float bowl, a sealed chamber, acts as a reservoir for the fuel. The float's position within the bowl directly influences the fuel level, dictating the opening and closing of the needle valve.

Venturi Effect: Mixing Fuel and Air

While the float mechanism ensures a consistent fuel supply, the actual mixing of fuel and air occurs within the venturi. This is a constricted section within the carburetor where the air velocity increases dramatically due to the Venturi effect. This effect states that an increase in the speed of a fluid occurs simultaneously with a decrease in fluid pressure.

The Venturi: Airflow Acceleration and Pressure Drop

The venturi is strategically designed to cause a significant pressure drop. As air is drawn into the carburetor by the engine's intake stroke, it accelerates through the venturi, resulting in a reduced pressure zone. This low-pressure area is crucial for drawing fuel from the float bowl into the air stream.

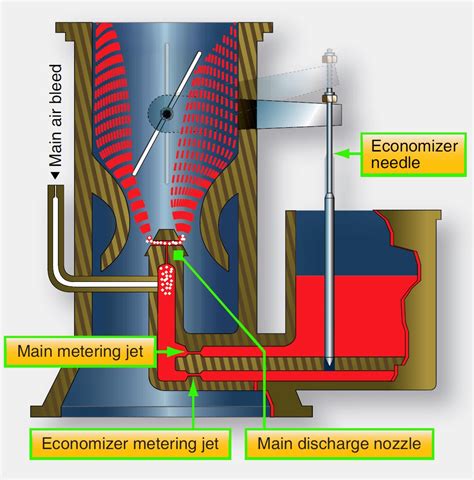

The Main Jet: Precise Fuel Delivery

Located within the venturi, the main jet is a precisely sized orifice that meters the fuel flow. The pressure differential between the float bowl (relatively high pressure) and the venturi (low pressure) forces fuel through the main jet. The size of the main jet determines the amount of fuel delivered to the engine at a given airflow rate. The carefully calculated size is crucial for ensuring the correct air-fuel ratio.

The Air-Fuel Mixture: Achieving Optimal Combustion

The combination of the venturi effect and the main jet creates a well-mixed air-fuel mixture. The finely atomized fuel from the main jet mixes effectively with the fast-moving air, creating a homogeneous mixture ready for combustion in the engine's cylinders. The precise balance between air and fuel is crucial for optimum engine performance and efficiency. Too much fuel leads to a rich mixture, reducing fuel efficiency and potentially causing fouling of spark plugs. Too little fuel leads to a lean mixture, resulting in incomplete combustion and potential engine damage.

Idle System: Maintaining the Mixture at Low Engine Speeds

The main system described above functions efficiently at higher engine speeds. However, at idle, the airflow through the venturi is low, and the vacuum is insufficient to draw fuel through the main jet effectively. This necessitates an idle system.

Idle Circuit: Ensuring Stable Operation at Low Speeds

The idle circuit is a separate system that delivers fuel directly to the engine at low speeds. It typically includes a small jet and passageways that bypass the main venturi. The idle circuit ensures a stable air-fuel mixture when the engine is idling. Adjusting the idle mixture screw affects the fuel flow in the idle circuit allowing the fine-tuning of the air-fuel ratio for optimal idle performance.

Idle Speed Screw: Fine-Tuning the Idle Mixture

The idle speed screw controls the amount of air entering the idle system. Adjusting this screw allows the fine-tuning of the idle mixture, ensuring smooth operation at low engine speeds.

Accelerator Pump: Compensating for Sudden Acceleration

Sudden acceleration demands a quick increase in fuel delivery to prevent engine stalling or hesitation. The accelerator pump addresses this.

The Accelerator Pump: Immediate Fuel Enrichment

The accelerator pump is a small pump activated when the accelerator pedal is pressed quickly. This pump injects a shot of extra fuel into the venturi, enriching the mixture momentarily and ensuring smooth acceleration. This prevents the engine from leaning out and stumbling under sudden acceleration.

Diaphragm Mechanism: Delivering a Precise Fuel Shot

The accelerator pump often utilizes a diaphragm mechanism. When the accelerator pedal is depressed, the diaphragm is activated, creating pressure that forces fuel from the float bowl into the venturi, providing that momentary boost of fuel.

Choke System: Cold Start Enrichment

Starting a cold engine requires a richer fuel-air mixture. The choke system facilitates this.

The Choke: Restricting Airflow for Easier Starting

The choke is a device that restricts the airflow entering the carburetor when the engine is cold. This restriction creates a richer fuel-air mixture, enabling easier starting and warming up of the engine. Once the engine is warmed up, the choke is gradually opened, allowing normal airflow. Modern systems often use automatic chokes which automatically adjust the airflow depending on engine temperature.

Manual Choke vs. Automatic Choke

Older carburetors featured manual chokes, requiring the driver to manually engage and disengage the choke. More modern systems employ automatic chokes, which operate automatically based on engine temperature sensors. These systems simplify the starting process and provide more efficient cold-start enrichment.

Maintaining and Tuning Your Carburetor: Ensuring Optimal Performance

Float-type carburetors, while relatively simple in design, require regular maintenance and occasional tuning to ensure optimal engine performance.

Regular Maintenance: Keeping it Running Smoothly

Regular maintenance includes checking the float level, cleaning the jets, and inspecting the various components for wear and tear. A clean carburetor ensures smooth operation and prevents fuel delivery issues. Ignoring maintenance can lead to poor fuel economy, rough idling, and even engine damage.

Tuning the Carburetor: Fine-Tuning the Mixture

Tuning the carburetor involves adjusting the idle mixture screw, the idle speed screw, and potentially replacing worn or damaged parts. Proper tuning ensures optimal performance and fuel efficiency. However, carburetor tuning is a specialized task, often requiring experience and specialized tools.

Conclusion: A Legacy of Precision Engineering

The float-type carburetor, while largely replaced by fuel injection in modern vehicles, represents a remarkable piece of engineering. Its elegant design and precise metering of fuel and air allowed for reliable and efficient engine operation for decades. Understanding its operating principles allows for a deeper appreciation of the internal combustion engine and the sophisticated mechanisms involved in delivering the perfect air-fuel mixture for combustion. While they may be a relic of the past for many, understanding their functionality provides insights into the fundamentals of fuel delivery systems and the evolution of automotive technology. The intricate interplay between the float, the needle valve, the venturi, and the various jets showcase the ingenuity involved in creating a self-regulating system for consistent fuel delivery. The legacy of the float-type carburetor remains a testament to the precision and elegance of mechanical engineering.

Latest Posts

Latest Posts

-

Juror 8 Quotes With Page Numbers

Apr 01, 2025

-

What Does This Passage Imply About Cousin

Apr 01, 2025

-

Gramatica C Subject Pronouns And Ser Answer Key

Apr 01, 2025

-

I Look Into My Glass Reveals Elements Of Romanticism Through

Apr 01, 2025

-

Discrete Mathematics With Applications 5th Edition Solutions Pdf

Apr 01, 2025

Related Post

Thank you for visiting our website which covers about The Operating Principle Of Float-type Carburetors Is Based On The . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.