The Precise Control Of Injected Fuel Quantity Is Known As:

Onlines

Mar 20, 2025 · 7 min read

Table of Contents

The Precise Control of Injected Fuel Quantity: A Deep Dive into Fuel Metering

The precise control of injected fuel quantity is paramount to modern engine performance, efficiency, and emissions. This crucial aspect of engine management is often referred to as fuel metering, encompassing a complex interplay of sensors, actuators, and sophisticated control algorithms. Understanding fuel metering is key to appreciating the advancements in internal combustion engine (ICE) technology and the ongoing push for cleaner, more efficient vehicles. This article delves into the intricacies of fuel metering, exploring various techniques, the challenges involved, and the future directions of this critical engine system.

The Importance of Precise Fuel Metering

Accurate fuel metering is not simply about achieving combustion; it's about optimizing it. Too much fuel leads to incomplete combustion, resulting in wasted energy, increased emissions (particularly unburnt hydrocarbons and carbon monoxide), and potentially damaging engine components. Too little fuel leads to lean combustion, potentially causing misfires, overheating, and even engine damage. The ideal air-fuel ratio, often expressed as a lambda value (λ), is crucial for efficient and clean combustion. Lambda 1 (λ=1) represents a stoichiometric mixture – the ideal ratio of air to fuel for complete combustion. Modern engines aim to control this ratio precisely, adjusting it dynamically based on operating conditions.

Key Benefits of Precise Fuel Metering:

- Improved Fuel Economy: Precise fuel metering ensures that only the necessary amount of fuel is used for optimal combustion, minimizing wasted fuel.

- Reduced Emissions: By maintaining the optimal air-fuel ratio, pollutant emissions such as NOx, CO, and HC are significantly reduced.

- Enhanced Engine Performance: Precise fuel control contributes to smoother engine operation, improved power output, and better responsiveness.

- Extended Engine Lifespan: By preventing lean or rich combustion conditions, the risk of engine damage is minimized, extending its lifespan.

Methods of Fuel Metering

Several methods are employed for precise fuel metering, each with its own advantages and disadvantages. These methods have evolved significantly over time, moving from simple mechanical systems to sophisticated electronic control.

1. Mechanical Fuel Metering Systems (Older Technology):

- Carburetors: These older systems use a venturi effect to draw fuel into the airstream, mixing it with air before entering the engine cylinders. While simple, carburetors offer limited precision and are highly sensitive to environmental factors (temperature, altitude). They are largely obsolete in modern vehicles.

- Mechanical Fuel Injection: Early fuel injection systems used mechanical pumps and metering units to deliver fuel to the engine. These systems offer improved precision over carburetors but lack the adaptability and flexibility of electronic systems.

2. Electronic Fuel Metering Systems (Modern Technology):

- Port Fuel Injection (PFI): Fuel is injected into the intake port just before the intake valve. This method is relatively simple and cost-effective, allowing for reasonably precise fuel control.

- Direct Injection (DI): Fuel is injected directly into the combustion chamber. DI offers significant advantages in terms of fuel efficiency, power output, and emissions control. It enables precise control of fuel spray pattern and timing, leading to more efficient combustion.

- Gasoline Direct Injection (GDI): This is a specific type of DI used in gasoline engines, offering better fuel efficiency compared to PFI.

- Common Rail Injection: Used extensively in diesel engines, a high-pressure rail supplies fuel to multiple injectors, allowing for precise and independent control of fuel injection timing and quantity for each cylinder.

- Multiple Point Injection: This system employs multiple injectors for each cylinder, offering an even higher level of control over fuel delivery. This improves atomization and combustion efficiency.

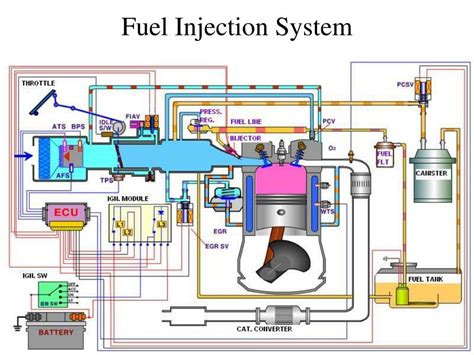

Components of Electronic Fuel Metering Systems

Sophisticated electronic fuel metering systems rely on a network of interconnected components working in harmony. These components constantly monitor and adjust fuel delivery based on various operating parameters.

Key Components:

- Fuel Pump: Delivers fuel from the tank to the fuel rail under sufficient pressure. The pressure is precisely regulated by a fuel pressure regulator.

- Fuel Injectors: Precisely metered amounts of fuel are released into the engine based on signals from the engine control unit (ECU). The injectors are electromagnetically activated and their opening and closing times determine the injected fuel quantity.

- Engine Control Unit (ECU): The ECU is the "brain" of the fuel metering system. It receives inputs from various sensors, processes this data, and calculates the precise amount of fuel needed for optimal combustion. It then sends signals to the fuel injectors to regulate the fuel delivery.

- Sensors: Several sensors provide crucial feedback to the ECU, including:

- Mass Airflow Sensor (MAF): Measures the amount of air entering the engine.

- Throttle Position Sensor (TPS): Indicates the throttle opening, reflecting the driver’s demand for power.

- Manifold Absolute Pressure (MAP) Sensor: Measures the pressure in the intake manifold.

- Crankshaft Position Sensor (CKP): Detects the crankshaft's rotational position, enabling precise timing of fuel injection.

- Oxygen Sensor (O2 sensor or Lambda Sensor): Measures the oxygen content in the exhaust gas, providing feedback on the air-fuel ratio. This is crucial for closed-loop control of fuel delivery.

- Fuel Rail: A high-pressure pipe distributing fuel to the injectors.

Closed-Loop Control: The Feedback Mechanism

Modern fuel metering systems operate using a closed-loop control system. This means the system constantly monitors the air-fuel ratio and adjusts fuel delivery based on the feedback received from the oxygen sensor (O2 sensor). The O2 sensor measures the oxygen content in the exhaust gases, providing information on whether the mixture is rich (too much fuel) or lean (too little fuel). The ECU uses this information to continuously fine-tune the fuel injection strategy, maintaining the optimal air-fuel ratio for efficient and clean combustion.

Challenges in Fuel Metering

Despite significant advancements, achieving perfect fuel metering remains a challenge.

Key Challenges:

- Transient Conditions: Rapid changes in engine speed and load (such as acceleration or deceleration) require the fuel metering system to respond quickly and accurately, which can be complex to achieve.

- Cold Start: Starting a cold engine requires a richer fuel mixture to ensure proper ignition and warm-up. Precisely controlling this enrichment phase is crucial.

- Variations in Fuel Quality: Fuel quality can vary significantly, affecting combustion efficiency. The fuel metering system needs to adapt to these variations to maintain optimal performance.

- Emission Regulations: Stringent emission regulations constantly push for more precise and efficient fuel metering to minimize pollutants.

- Engine Wear and Tear: Over time, engine components wear, impacting the accuracy of various sensors and actuators. Regular maintenance is essential to maintain precise fuel control.

Future Directions in Fuel Metering

The quest for even more precise and efficient fuel metering continues. Several areas of research and development are shaping the future of this technology.

Key Developments:

- Advanced Sensors and Actuators: More accurate and responsive sensors and actuators are being developed to provide even finer control over fuel delivery.

- Improved Control Algorithms: Sophisticated control algorithms, leveraging artificial intelligence and machine learning, are being developed to optimize fuel metering strategies under various operating conditions.

- Integration with other Engine Systems: Fuel metering is increasingly integrated with other engine systems, such as variable valve timing (VVT) and turbocharging, to maximize overall efficiency and performance.

- Alternative Fuels: As the automotive industry explores alternative fuels (biofuels, hydrogen), fuel metering systems will need to adapt to the unique characteristics of these fuels.

- Predictive Fuel Control: Future systems may employ predictive models to anticipate changes in engine load and preemptively adjust fuel delivery, leading to even smoother and more efficient operation.

Conclusion

The precise control of injected fuel quantity, or fuel metering, is a cornerstone of modern engine technology. The evolution from simple mechanical systems to sophisticated electronic controls reflects the relentless pursuit of improved fuel efficiency, reduced emissions, and enhanced performance. Ongoing research and development continue to push the boundaries of fuel metering, promising even cleaner and more efficient vehicles in the future. The complexities involved highlight the remarkable engineering behind even seemingly simple aspects of a modern car's operation. A deep understanding of fuel metering offers insights into the intricate interplay between sensors, actuators, and control systems that are essential for the smooth and efficient operation of our vehicles.

Latest Posts

Latest Posts

-

All Music Has A Strong Discernable Beat

Mar 20, 2025

-

Barriers To Quality Healthcare Include All Of The Following Except

Mar 20, 2025

-

Till We Have Faces Summary Sparknotes

Mar 20, 2025

-

The Prokaryotic Cells That Built Stromatolites Are Classified As

Mar 20, 2025

-

Do Androids Dream Of Electric Sheep Characters

Mar 20, 2025

Related Post

Thank you for visiting our website which covers about The Precise Control Of Injected Fuel Quantity Is Known As: . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.