Unit 5 Bill Of Materials Answers

Onlines

Mar 12, 2025 · 5 min read

Table of Contents

Decoding Unit 5 Bill of Materials: A Comprehensive Guide

Understanding a Bill of Materials (BOM) is crucial in various fields, especially manufacturing and engineering. Unit 5, often referring to a specific course or module in a broader curriculum, likely delves deeper into the complexities of BOMs. This comprehensive guide will dissect the intricacies of Unit 5 BOM questions, providing answers and a solid understanding of the underlying concepts. We'll cover various aspects, from basic BOM structures to advanced applications and potential problem-solving strategies.

What is a Bill of Materials (BOM)?

A Bill of Materials is a comprehensive list of all the raw materials, components, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product. It's the foundational document for production planning, procurement, and cost estimation. Think of it as the recipe for a complex product. A well-structured BOM ensures efficient production, minimizes waste, and aids in accurate costing.

Key Elements of a BOM:

- Item Number: A unique identifier for each component.

- Description: A detailed description of the component, including specifications and tolerances.

- Quantity: The number of units required for one assembly of the end product.

- Unit of Measure: The unit in which the quantity is measured (e.g., each, meters, kilograms).

- Material Code: A code used for inventory management and tracking.

- Cost: The cost of each component.

Types of BOM Structures

BOMs can be structured in various ways, depending on the complexity of the product and the manufacturing process. Common structures include:

- Single-Level BOM: This lists only the immediate components needed to assemble the final product. It's simple but lacks detail on sub-assemblies.

- Multi-Level BOM: This shows all components, including sub-assemblies and sub-components, in a hierarchical structure. It provides a complete picture of the entire manufacturing process.

- Indented BOM: A visually organized multi-level BOM, where components are indented to show their hierarchical relationship. This improves readability and comprehension.

- Exploded BOM: A graphical representation of a multi-level BOM, often used in design and engineering. It visually depicts the assembly process.

Common Challenges in Unit 5 BOM Exercises

Unit 5 BOM exercises often present challenges that test a student's understanding beyond simply listing components. These challenges might include:

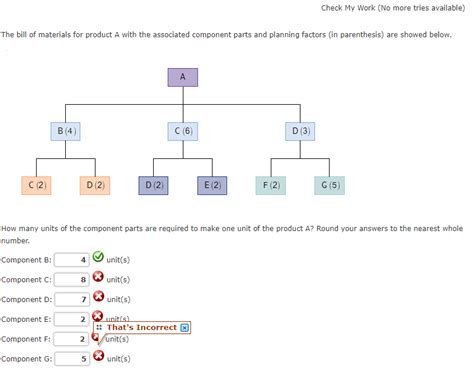

- Calculating Total Quantities: Determining the total quantity of each component needed for a specified number of end products. This requires understanding the relationships between components at different levels of the BOM.

- Identifying Missing Components: Spotting missing components in an incomplete BOM. This tests attention to detail and understanding of the assembly process.

- Analyzing Cost Implications: Calculating the total cost of materials based on the BOM and unit costs of individual components. This highlights the importance of BOM accuracy in cost control.

- Managing BOM Revisions: Understanding how changes in design or specifications affect the BOM and the need for proper version control.

- Understanding Phantom BOMs: These are BOMs for sub-assemblies that are not stocked independently but are assembled directly into higher-level assemblies. Mastering these requires a deep understanding of the manufacturing flow.

Advanced BOM Concepts Often Covered in Unit 5

- Modular BOMs: These are used when products are made up of interchangeable modules. This is especially relevant for mass customization and configurable products.

- Common BOMs: These are used when multiple products share common components. This allows for efficient inventory management and cost savings.

- Engineering Change Orders (ECOs): These document changes to a BOM, ensuring traceability and consistency.

- BOM Data Management: This involves using software to manage and update BOMs, streamlining the entire process. This is increasingly important in today's complex manufacturing environments.

Example Problems and Solutions

Let's work through a few example problems that illustrate the concepts discussed above:

Problem 1: Calculating Total Quantities

A simple bicycle requires the following components:

- Frame: 1

- Wheels: 2

- Handlebars: 1

- Seat: 1

You need to manufacture 100 bicycles. Calculate the total quantity of each component required.

Solution:

- Frame: 100 x 1 = 100

- Wheels: 100 x 2 = 200

- Handlebars: 100 x 1 = 100

- Seat: 100 x 1 = 100

Problem 2: Identifying Missing Components

A company manufactures a simple lamp. The provided BOM is incomplete:

- Lamp Base: 1

- Lamp Shade: 1

- Wiring: ?

- Light Bulb: 1

Identify the missing component.

Solution: The missing component is Wiring. A lamp requires wiring to function.

Problem 3: Analyzing Cost Implications

Using the bicycle BOM from Problem 1, assume the following costs:

- Frame: $50

- Wheels: $15 each

- Handlebars: $10

- Seat: $20

Calculate the total material cost for 100 bicycles.

Solution:

- Frame cost: 100 x $50 = $5000

- Wheel cost: 200 x $15 = $3000

- Handlebar cost: 100 x $10 = $1000

- Seat cost: 100 x $20 = $2000

- Total Material Cost: $5000 + $3000 + $1000 + $2000 = $11000

Problem 4: Multi-Level BOM Example

Consider a simple chair assembly:

- Chair (1):

- Legs (4)

- Seat (1)

- Backrest (1)

- Seat (1):

- Seat Frame (1)

- Cushion (1)

- Backrest (1):

- Backrest Frame (1)

- Cushion (1)

This is a multi-level BOM. To assemble 50 chairs, you'd need:

- Legs: 50 x 4 = 200

- Seat Frames: 50 x 1 = 50

- Seat Cushions: 50 x 1 = 50

- Backrest Frames: 50 x 1 = 50

- Backrest Cushions: 50 x 1 = 50

This example shows how a multi-level BOM helps in calculating the total quantity of each component needed for a larger production run.

Tips for Success in Unit 5 BOM Assessments

- Practice Regularly: Work through various BOM examples to build your skills.

- Visualize the Assembly Process: Understanding how the components fit together will aid in identifying missing parts or potential errors.

- Use Software Tools: Explore BOM management software to understand their capabilities.

- Focus on the Fundamentals: Ensure a strong grasp of basic BOM structure and terminology.

- Understand the Different BOM Types: Be familiar with the various BOM structures and their applications.

- Pay close attention to details: Small errors in quantities or component specifications can lead to significant problems in production.

By thoroughly understanding these concepts and practicing regularly, you'll be well-prepared to tackle any Unit 5 Bill of Materials questions and master the art of BOM management. Remember that a well-structured BOM is the backbone of efficient and cost-effective manufacturing.

Latest Posts

Latest Posts

-

Raises And Other Monetary Incentives Are Examples Of Rewards

Mar 12, 2025

-

Agent Handlers Are A Solution To Low Bandwidth

Mar 12, 2025

-

Quotes In Like Water For Chocolate

Mar 12, 2025

-

All Of The Following Are Specifics Of Unscheduled Telework Except

Mar 12, 2025

-

You Witch The Original Symbol Of Female Power Answer Key

Mar 12, 2025

Related Post

Thank you for visiting our website which covers about Unit 5 Bill Of Materials Answers . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.