What Of The Following Revolutionized The Steel Industry

Onlines

Apr 07, 2025 · 5 min read

Table of Contents

What Revolutionized the Steel Industry? A Deep Dive into Key Innovations

The steel industry, a cornerstone of modern infrastructure and technological advancement, has undergone dramatic transformations throughout history. From rudimentary blacksmithing to the mass production of high-strength alloys, numerous innovations have revolutionized its processes, products, and impact on society. This article explores some of the most significant breakthroughs that have reshaped the steel industry, examining their impact and lasting legacy.

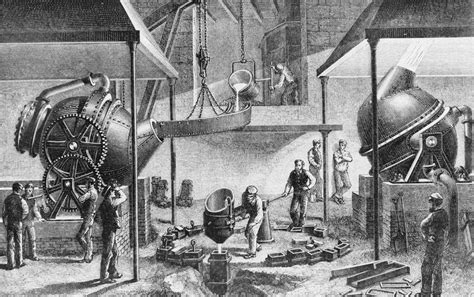

The Bessemer Process: A Turning Point in Steel Production

Before the mid-19th century, steel production was a laborious and expensive process, limiting its widespread adoption. Wrought iron, a less efficient material, dominated construction and manufacturing. The invention of the Bessemer process in 1856 by Henry Bessemer marked a pivotal moment. This revolutionary technique involved blowing air through molten pig iron to remove impurities like carbon, drastically reducing production time and cost.

Impact of the Bessemer Process:

- Mass Production: The Bessemer process enabled the mass production of steel, transforming it from a luxury material to a readily available commodity.

- Cost Reduction: Significantly lower production costs made steel affordable for a wider range of applications.

- Infrastructure Development: The availability of cheap steel fueled the rapid expansion of railroads, bridges, and skyscrapers, reshaping urban landscapes and facilitating global trade.

- Technological Advancements: The process's efficiency spurred further innovation in steelmaking technologies and related industries.

The Siemens-Martin Process (Open-Hearth Furnace): Refining Steel Quality

While the Bessemer process revolutionized steel production speed, it had limitations in controlling the final product's chemical composition. The Siemens-Martin process, developed independently by William Siemens and Pierre-Emile Martin in the 1860s, addressed this shortcoming. Utilizing a regenerative furnace, it allowed for more precise control over the steel's chemical composition, producing higher-quality steel with improved properties.

Advantages of the Siemens-Martin Process:

- Improved Quality: Greater control over the chemical composition resulted in higher-quality, more consistent steel.

- Versatility: The process could handle a wider range of scrap metal, reducing waste and improving cost-effectiveness.

- Alloying Capabilities: The open-hearth furnace facilitated the introduction of alloying elements, enhancing steel's properties for specific applications.

The Basic Oxygen Furnace (BOF): Speed and Efficiency Redefined

The mid-20th century saw the emergence of the Basic Oxygen Furnace (BOF), another landmark innovation in steelmaking. This process dramatically reduced the time required to refine molten iron, achieving comparable quality to the open-hearth furnace with significantly increased speed and efficiency.

Key Advantages of the BOF:

- Speed and Efficiency: The BOF drastically reduced production time, making it significantly more productive than previous methods.

- Cost-Effectiveness: Lower production time translated into lower energy consumption and overall cost savings.

- Automation Potential: The BOF was more easily automated, leading to greater efficiency and reduced labor costs.

Electric Arc Furnace (EAF): Recycling and Sustainability

The latter half of the 20th century saw the rise of the Electric Arc Furnace (EAF), an increasingly prominent method for steel production. Unlike the BOF and open-hearth furnace, the EAF uses electricity to melt scrap metal, making it particularly suitable for recycling steel.

Significance of the EAF:

- Sustainability: The EAF's reliance on scrap metal promotes recycling and reduces the environmental impact of steel production.

- Flexibility: EAFs are highly versatile, capable of producing a wide range of steel grades tailored to specific applications.

- Cost-Effectiveness (in Certain Circumstances): In regions with abundant scrap metal and relatively inexpensive electricity, EAFs can be very cost-effective.

Continuous Casting: Streamlining the Production Process

While advancements in steelmaking focused on refining the molten metal, the process of solidifying and shaping the steel also underwent a significant transformation. The introduction of continuous casting revolutionized this aspect of steel production. Instead of pouring molten steel into ingots that needed further processing, continuous casting allows for the direct solidification of steel into semi-finished products like slabs, blooms, and billets.

Benefits of Continuous Casting:

- Increased Efficiency: Eliminates the need for ingot casting and reheating, resulting in significant time and energy savings.

- Improved Quality: Reduces the risk of defects associated with traditional casting methods.

- Higher Productivity: Enables higher production rates and improved overall productivity.

Advanced Steelmaking Technologies: Tailoring Steel for Specific Needs

Modern steelmaking has moved beyond simply refining iron into steel. Sophisticated technologies allow for the precise control of steel's composition and microstructure, leading to the development of advanced high-strength steels with enhanced properties like higher tensile strength, improved formability, and superior corrosion resistance.

Examples of Advanced Steelmaking Technologies:

- Thermo-mechanical Processing: Combining heat treatment and mechanical deformation to optimize the steel's microstructure and properties.

- Controlled Rolling: Precisely controlling the rolling process to achieve specific grain structures and enhance mechanical properties.

- Advanced Alloying: Introducing carefully selected alloying elements to tailor the steel's properties for particular applications.

The Rise of Automation and Robotics: Transforming Steel Production

The steel industry has embraced automation and robotics to enhance efficiency, improve safety, and increase productivity. From automated material handling systems to robotic welding and cutting, these technologies have transformed many aspects of steel production.

Impact of Automation and Robotics:

- Increased Efficiency: Automated systems optimize production processes, reducing downtime and increasing output.

- Improved Safety: Robots handle dangerous tasks, minimizing risks to human workers.

- Enhanced Precision: Automated systems ensure greater precision and consistency in steel production.

The Future of Steel: Sustainability and Innovation

The steel industry is continuously evolving, driven by the need for sustainability and the pursuit of innovative materials. Research and development efforts are focused on:

- Reducing Carbon Emissions: Developing more environmentally friendly steelmaking processes with a reduced carbon footprint.

- Developing High-Performance Steels: Creating new steel alloys with superior properties for advanced applications in aerospace, automotive, and energy sectors.

- Improving Recycling Rates: Optimizing recycling processes to maximize the reuse of scrap metal and minimize waste.

- Implementing Advanced Manufacturing Techniques: Utilizing additive manufacturing (3D printing) and other innovative techniques to produce customized steel components.

Conclusion: A Continuous Evolution

The steel industry's journey from rudimentary methods to sophisticated high-tech processes exemplifies human ingenuity and adaptability. From the Bessemer process to the latest advancements in automation and sustainability, each innovation has built upon previous breakthroughs, driving the industry forward and shaping the world we live in. The ongoing quest for efficiency, sustainability, and enhanced material properties ensures that the steel industry's evolution will continue to be a fascinating story of innovation and progress. The future of steel is bright, promising advancements that will further revolutionize industries and shape the world for generations to come.

Latest Posts

Latest Posts

-

Label The Muscles In The Following Illustration

Apr 08, 2025

-

Correctly Label The External Anatomy Of The Anterior Heart

Apr 08, 2025

-

What Is The Theme Of Button Button

Apr 08, 2025

-

Cress Insurance Company Completing A Flyer

Apr 08, 2025

-

A Researcher Claims That The Synthesis Of Atp From Adp

Apr 08, 2025

Related Post

Thank you for visiting our website which covers about What Of The Following Revolutionized The Steel Industry . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.