Where Are The Materials To Be Used For Walls Found

Onlines

Mar 26, 2025 · 7 min read

Table of Contents

- Where Are The Materials To Be Used For Walls Found

- Table of Contents

- Where Are the Materials to Be Used for Walls Found? A Comprehensive Guide

- Common Walling Materials and Their Sources

- 1. Bricks: From Clay to Construction

- 2. Concrete Blocks (Cinder Blocks): A Blend of Aggregates

- 3. Timber: From Forests to Framing

- 4. Stone: From Quarries to Walls

- 5. Insulated Concrete Forms (ICFs): A Modern Approach

- 6. Other Walling Materials

- The Importance of Sustainable Sourcing

- Conclusion

- Latest Posts

- Latest Posts

- Related Post

Where Are the Materials to Be Used for Walls Found? A Comprehensive Guide

Building a wall, whether for a house, a garden feature, or a larger structure, requires careful consideration of the materials used. The choice of material significantly impacts the wall's aesthetics, durability, cost, and environmental impact. But where exactly are these materials found? This comprehensive guide explores the sourcing of common walling materials, from readily available options to those requiring more specialized sourcing.

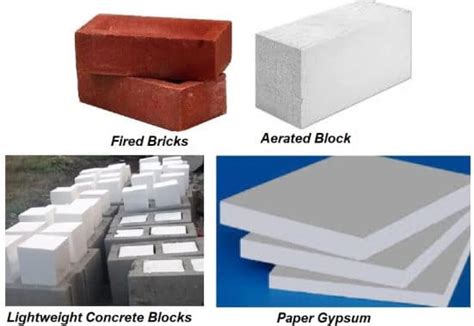

Common Walling Materials and Their Sources

This section will explore the origin and sourcing of popular walling materials:

1. Bricks: From Clay to Construction

Bricks, a classic and enduring building material, are primarily made from clay. This abundant natural resource is found globally, although its composition and quality vary considerably depending on location.

-

Clay Sourcing: Clay deposits are often found in sedimentary formations, riverbeds, and floodplains. The clay is extracted through mining or quarrying operations, depending on the size and depth of the deposit. The quality of clay, its plasticity, and its firing properties, are crucial factors influencing the brick's final strength and durability. Different regions produce bricks with unique characteristics due to variations in their clay composition.

-

Brick Manufacturing: Once extracted, the clay undergoes processing, including mixing, shaping (often through extrusion or molding), and drying. Finally, the bricks are fired in kilns at high temperatures, transforming them into hard, durable building units. The location of brick manufacturing plants is usually near clay deposits to minimize transportation costs. Some brick manufacturers even specialize in using recycled materials, incorporating industrial byproducts into their mix.

-

Brick Availability: Bricks are widely available globally, though specific types and colors might be regionally limited due to the clay's unique characteristics. Local brickyards often supply construction projects, reducing transportation distances and environmental impact.

2. Concrete Blocks (Cinder Blocks): A Blend of Aggregates

Concrete blocks, also known as cinder blocks or concrete masonry units (CMUs), are made from a mixture of cement, aggregates (such as sand, gravel, or crushed stone), and water.

-

Cement Sourcing: Cement manufacturing is a global industry, with plants typically located near sources of limestone, clay, and gypsum – the primary raw materials. These materials are quarried and then processed in specialized plants to produce cement, a key component of concrete blocks.

-

Aggregate Sourcing: Aggregates, the bulk component of concrete blocks, are sourced from various locations. Sand and gravel are often obtained from riverbeds, quarries, or coastal deposits. Crushed stone is produced by crushing larger rocks, typically obtained from quarries. The specific type of aggregate used can affect the block's strength, appearance, and cost. Recycled materials like crushed concrete or glass are increasingly used as aggregates in sustainable construction projects.

-

Concrete Block Manufacturing: Concrete blocks are manufactured in pre-cast plants. The mixture of cement, aggregates, and water is poured into molds, vibrated to consolidate, and then cured to harden. These plants are frequently located near sources of aggregates to reduce transportation expenses.

-

Concrete Block Availability: Concrete blocks are readily available worldwide, with various sizes, strengths, and finishes available. Their widespread use makes them a cost-effective and readily accessible walling material.

3. Timber: From Forests to Framing

Timber framing has a long history and remains a popular walling material, particularly for aesthetic and sustainable building projects.

-

Timber Sourcing: Timber is harvested from forests managed sustainably. Responsible forestry practices prioritize replanting and ensure the long-term health of forests. The type of timber used, whether softwood or hardwood, depends on the structural requirements and aesthetic preferences.

-

Timber Processing: After harvesting, timber undergoes processing, including milling to produce lumber of various dimensions and grades. The processing often involves drying to reduce moisture content and prevent warping. The location of sawmills and timber treatment facilities is typically near forests to minimize transport distances.

-

Timber Availability: The availability of timber varies depending on the region and the species of tree. Sustainable sourcing practices are increasingly important to ensure the long-term availability of timber resources. Certification programs, such as the Forest Stewardship Council (FSC), provide assurance that timber comes from responsibly managed forests. The increasing use of engineered timber products, such as laminated veneer lumber (LVL), also expands the available options and improves the material's performance characteristics.

4. Stone: From Quarries to Walls

Stone, a durable and visually appealing material, has been used for building walls for centuries.

-

Stone Sourcing: Stone is quarried from natural rock formations. The type of stone, such as granite, limestone, sandstone, or slate, dictates its properties, aesthetic, and cost. Quarrying operations can involve extensive excavation and processing.

-

Stone Processing: Depending on the type and intended use of the stone, it may undergo various processing steps, including cutting, shaping, and finishing. The processing often involves specialized equipment and expertise. The location of stone processing facilities is typically near the quarries to minimize transport costs and reduce environmental impact.

-

Stone Availability: The availability of stone is geographically limited, with certain types of stone more abundant in specific regions. The cost and availability of stone can vary significantly depending on the type of stone, its accessibility, and the distance from the quarry to the construction site.

5. Insulated Concrete Forms (ICFs): A Modern Approach

ICFs are a modern walling system that combines concrete and insulation.

-

ICF Sourcing: ICFs are manufactured from expanded polystyrene (EPS) or extruded polystyrene (XPS) foam, which are commonly produced from petroleum-based feedstocks. Cement, used in filling the ICF forms, is sourced as discussed in the concrete block section.

-

ICF Manufacturing: ICF blocks are manufactured in pre-cast plants, involving molding the foam into specific shapes and providing interlocking features for easy assembly on-site. These facilities are often strategically located to reduce transportation costs and times.

-

ICF Availability: ICFs are becoming increasingly available worldwide, appealing to builders focusing on energy efficiency and fast construction methods. The sourcing of the foam component is important to consider from an environmental standpoint, with increasing interest in using recycled materials in foam production.

6. Other Walling Materials

Many other materials are used for wall construction depending on regional availability and the project requirements. These include:

-

Adobe: Made from sun-dried earth and straw, adobe is common in arid climates where suitable soil is readily available.

-

Cob: A mixture of earth, sand, straw, and water, cob is a natural building material widely used for walls in sustainable construction.

-

Rammed Earth: Compressed layers of compacted earth, stabilized with cement or other binders.

-

Recycled Materials: Increasingly, recycled materials like shipping containers, reclaimed wood, and repurposed metal are being utilized creatively in wall construction.

The Importance of Sustainable Sourcing

The sourcing of walling materials significantly impacts the environmental sustainability of a construction project. Sustainable sourcing considers:

-

Minimizing Environmental Impact: Choosing locally sourced materials reduces transportation distances and associated carbon emissions. Selecting materials with low embodied energy, meaning they require less energy to produce and transport, is crucial for a reduced environmental footprint.

-

Responsible Forestry Practices: Using timber sourced from sustainably managed forests ensures the long-term health of ecosystems and reduces deforestation.

-

Supporting Local Economies: Sourcing materials locally supports local businesses and jobs, contributing positively to the community.

-

Recycling and Waste Reduction: Utilizing recycled materials reduces landfill waste and conserves natural resources.

Conclusion

The materials used for walls are sourced from a wide range of locations and through various processes. Understanding the origins of these materials, from the extraction of raw materials to manufacturing and transportation, is crucial for making informed decisions about construction. Considering the environmental impact and promoting sustainable sourcing practices are essential for ensuring the long-term availability of resources and reducing the carbon footprint of building projects. The choice of walling material also depends on many factors like budget, aesthetic preferences, climate, and local building codes. This guide serves as a starting point for investigating the origin of your preferred wall materials and contributes to informed decision-making in your construction projects.

Latest Posts

Latest Posts

-

Having A Learner Select Which Items

Mar 27, 2025

-

A Means End Chain Is Used In Planning To Show

Mar 27, 2025

-

When Preparing A Pr And C You Must

Mar 27, 2025

-

The Media Is A Powerful Influence Because It

Mar 27, 2025

-

Advanced Hardware Lab 6 2 Select And Install Adapter Cards

Mar 27, 2025

Related Post

Thank you for visiting our website which covers about Where Are The Materials To Be Used For Walls Found . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.