A Power Miter Saw Combines A Miter Box With A

Onlines

Mar 19, 2025 · 6 min read

Table of Contents

A Power Miter Saw: Combining Precision and Power

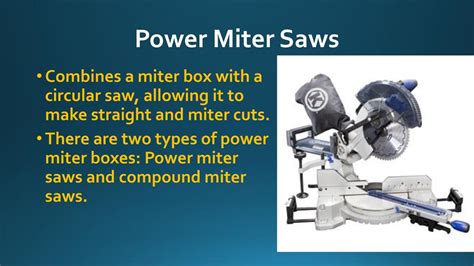

The power miter saw, a cornerstone of any serious woodworking shop, seamlessly blends the accuracy of a traditional miter box with the speed and power of a circular saw. This powerful tool allows for precise cuts on a variety of materials, making it indispensable for everything from intricate crown molding installations to straightforward lumber cuts. Understanding its capabilities, limitations, and proper usage is crucial for achieving clean, safe, and efficient results. This comprehensive guide delves into the intricacies of the power miter saw, exploring its features, benefits, safety precautions, and maintenance tips to help you master this essential woodworking tool.

Understanding the Power Miter Saw: A Deeper Dive

The power miter saw's design elegantly combines two fundamental woodworking tools: the miter box and the circular saw. The miter box, traditionally a wooden or metal frame guiding a hand saw for precise angled cuts, provides the accuracy. The circular saw, with its powerful motor and spinning blade, delivers the cutting power. The power miter saw integrates these elements for a significantly enhanced woodworking experience.

Key Components and Features:

- Motor: The heart of the saw, providing the power to drive the blade. Higher horsepower motors typically mean faster cutting speeds and the ability to handle harder materials.

- Blade: The cutting element, available in various sizes and tooth configurations to optimize performance for different materials (wood, plastic, metal). The blade's teeth design (e.g., fine, medium, coarse) significantly affects the quality of the cut.

- Miter Mechanism: Allows for precise adjustment of the cutting angle, typically ranging from 0 to 45 degrees in either direction (left and right). Some advanced models offer even wider miter ranges, and bevel adjustments.

- Bevel Mechanism: Enables adjusting the blade angle relative to the workpiece, typically up to 45 degrees, offering versatility for creating compound miters (combining miter and bevel cuts).

- Fence: A straight guide for supporting the workpiece, ensuring accurate cuts. Adjustability is crucial for precise alignment.

- Work Support: Additional support features like extensions or clamps improve workpiece stability, particularly when cutting longer pieces.

- Dust Collection System: A crucial safety and cleanliness feature, designed to minimize dust inhalation and maintain a cleaner workspace. This can range from simple dust ports to integrated vacuum systems.

Advantages of Using a Power Miter Saw:

The power miter saw offers several significant advantages over traditional methods:

- Increased Efficiency: It drastically reduces the time and effort required for making accurate angled cuts compared to hand tools.

- Enhanced Precision: The precise miter and bevel adjustments ensure accuracy that is difficult to achieve with hand saws and miter boxes.

- Versatility: Handles a wide range of materials and cutting applications, from framing lumber to delicate moldings.

- Improved Safety: The built-in safety features, including blade guards and dust collection systems, help mitigate risks associated with woodworking.

- Reduced Physical Strain: The power miter saw significantly reduces the physical effort involved in cutting, making it ideal for prolonged use.

Types of Power Miter Saws:

Power miter saws are categorized based on several factors, including:

- Size: Saws are classified by the size of the blade they accommodate, typically ranging from 7-1/4 inches to 12 inches. Larger blades handle larger workpieces more easily.

- Capacity: The saw's capacity refers to the maximum workpiece size it can accommodate. This is influenced by both blade size and the saw's design.

- Features: Advanced features such as laser guides, digital displays, and integrated vacuum systems add to precision and convenience. Some models offer sliding features for handling extra-long workpieces.

- Type: Compound miter saws are the most common, allowing both miter and bevel adjustments. Single bevel saws only allow bevel cuts on one side.

Choosing the right saw depends on your woodworking projects and budget. For occasional DIY projects, a smaller, less expensive saw may suffice. Professional woodworkers typically require larger, more robust saws with advanced features.

Essential Safety Precautions When Using a Power Miter Saw:

Safety is paramount when operating a power miter saw. Always follow these precautions:

- Wear appropriate safety gear: This includes safety glasses or a face shield, hearing protection, and a dust mask. Work gloves are also recommended.

- Secure the workpiece: Ensure the material is firmly held in place using clamps or other support systems. Never attempt to hold the workpiece by hand during the cutting process.

- Keep your hands clear: Maintain a safe distance from the blade during operation. Never reach over the blade while it's running.

- Inspect the blade: Before each use, check for damage or dullness. Replace a damaged or dull blade immediately.

- Use the right blade: Select a blade appropriate for the material being cut. Using the wrong blade can result in poor cuts, damage to the saw, or injury.

- Maintain a clear workspace: Remove any obstructions around the saw. Ensure proper lighting and ventilation.

- Disconnect power: Always unplug the saw before making adjustments, cleaning, or performing maintenance.

- Know your limits: Avoid pushing the saw beyond its capabilities. For very large or hard materials, consider a more powerful saw.

Choosing the Right Blade:

The selection of the appropriate blade is crucial for achieving high-quality cuts. Consider these factors:

- Material: Different materials require different blade types. Hardwoods necessitate blades with a higher tooth count for smoother cuts, while softer woods may benefit from fewer, larger teeth for faster cutting.

- Tooth configuration: The arrangement and shape of the teeth influence the cut's smoothness and speed. Alternate top bevel (ATB) teeth offer smoother cuts, while flat-top teeth prioritize speed.

- Kerf: The width of the cut made by the blade. A thinner kerf (narrower cut) reduces material waste.

- Blade diameter: This determines the saw's cutting capacity. Larger diameters allow for cutting larger workpieces.

Experimentation and research will guide you in selecting the optimal blade for your specific needs.

Proper Maintenance of Your Power Miter Saw:

Regular maintenance ensures the longevity and performance of your power miter saw:

- Clean the saw regularly: Remove sawdust and debris from the saw's components after each use. Pay special attention to the motor vents, blade, and fence.

- Lubricate moving parts: Apply lubricant to moving parts, such as the miter mechanism and bevel mechanism, as needed. Consult your owner's manual for specific lubrication recommendations.

- Check the blade: Regularly inspect the blade for damage, dullness, or wear. Replace as necessary.

- Inspect the fence: Ensure the fence is straight and aligned correctly. Adjust or replace if needed.

- Inspect the dust collection system: Maintain the dust collection system to ensure optimal dust removal.

Advanced Techniques and Applications:

Mastering the power miter saw opens up a range of advanced techniques:

- Compound miters: Combining miter and bevel cuts to create intricate angles, crucial for molding, crown molding and trim work.

- Cutting curves: While not ideal for intricate curves, careful planning and multiple cuts can approximate curved shapes.

- Cutting various materials: With the right blades, you can cut various materials beyond wood, including plastics and certain metals. However, always consult the manufacturer's specifications.

Practicing these techniques with scrap material before tackling your project will significantly improve your results.

Conclusion:

The power miter saw is a powerful and versatile tool that can transform your woodworking capabilities. By understanding its features, safety protocols, and maintenance requirements, you can harness its precision and efficiency to create high-quality projects. Remember that safety is paramount, and regular maintenance is key to ensuring the longevity and performance of your tool. With practice and patience, you will master this essential woodworking tool and elevate your woodworking skills to new heights. Investing time in learning and mastering the power miter saw will undoubtedly pay off in the quality and efficiency of your woodworking endeavors.

Latest Posts

Latest Posts

-

The Beaks Of Finches Lab Answers Pdf

Mar 19, 2025

-

Character List Of Catcher In The Rye

Mar 19, 2025

-

Pedro Y Natalia No Nos Dan Las Gracias

Mar 19, 2025

-

The Epic Periodic Table Scavenger Hunt

Mar 19, 2025

-

A Health Facility Using Cloud Storage For Data Backup Is

Mar 19, 2025

Related Post

Thank you for visiting our website which covers about A Power Miter Saw Combines A Miter Box With A . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.