All Refrigeration Systems Must Have Accumulators To Operate Safely

Onlines

Mar 17, 2025 · 6 min read

Table of Contents

All Refrigeration Systems Must Have Accumulators to Operate Safely: A Comprehensive Guide

The smooth and safe operation of any refrigeration system hinges on several critical components, and among them, the accumulator stands out as a crucial element often overlooked. While not directly involved in the core refrigeration cycle itself, the accumulator plays a vital, often life-saving, role in preventing system malfunctions and ensuring safe operation. This article delves deep into the essential function of accumulators in refrigeration systems, exploring their working principles, various types, crucial applications, and the dire consequences of their absence. We'll also touch upon preventative maintenance strategies to keep your refrigeration system running optimally and safely.

Understanding the Role of an Accumulator in Refrigeration Systems

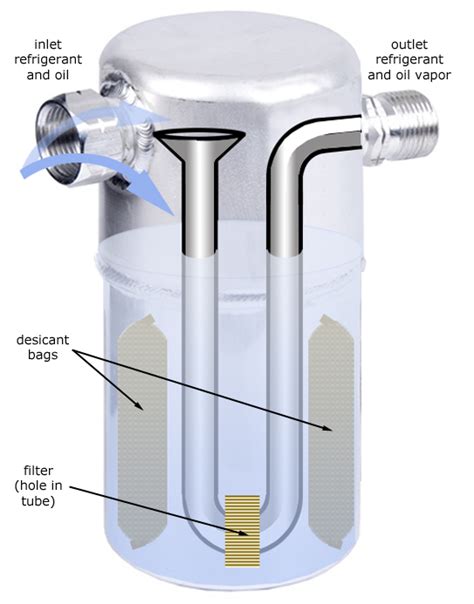

An accumulator, in the context of refrigeration, acts as a safety device and a liquid receiver. It's a pressure vessel designed to collect and store liquid refrigerant that may have entered the suction line. This liquid refrigerant poses a significant threat to the compressor, capable of causing severe damage or even catastrophic failure through a process known as liquid slugging.

Liquid slugging occurs when a significant amount of liquid refrigerant enters the compressor. The incompressible nature of liquid, unlike vapor, means the compressor's pistons can't effectively compress it. This leads to hydraulic lock, creating immense pressure within the system, potentially bending or breaking compressor components, damaging valves, and even causing the compressor to seize up completely.

The accumulator prevents liquid slugging by providing a reservoir where the excess liquid refrigerant can accumulate. This allows the compressor to draw primarily vapor, ensuring safe and efficient operation. It effectively acts as a buffer zone, preventing the sudden surge of liquid refrigerant into the compressor.

Types of Accumulators Used in Refrigeration Systems

Several types of accumulators cater to different refrigeration system designs and capacities. Choosing the right accumulator is critical for optimal performance and safety. The most common types include:

1. Vertical Accumulators: These are the most common type, characterized by their vertical cylindrical design. They are relatively simple and easy to install, making them suitable for various applications.

2. Horizontal Accumulators: Used where space is at a premium, horizontal accumulators save vertical space but might require more careful mounting and piping.

3. External Accumulators: These are separate units connected to the refrigeration system's suction line. They provide flexibility in placement and sizing.

4. Internal Accumulators: Integrated directly into the compressor's casing, these accumulators offer a compact design but are less accessible for inspection and maintenance.

The selection of an accumulator type depends on factors such as the refrigerant used, the system's capacity, the available space, and the desired level of accessibility for maintenance.

Why Accumulators are Absolutely Essential for Safe Operation

The absence of an accumulator in a refrigeration system exposes it to a considerable risk of:

-

Compressor Damage: As previously mentioned, liquid slugging is the most significant threat. The resulting damage can range from minor repairs to complete compressor replacement, incurring significant costs and downtime.

-

System Failure: Severe liquid slugging can lead to catastrophic system failure, requiring extensive repairs and potentially jeopardizing the entire refrigeration process.

-

Safety Hazards: System failures can create dangerous situations, especially in large-scale commercial or industrial applications. Refrigerant leaks can lead to exposure hazards for personnel, while pressure surges can cause damage to surrounding equipment.

-

Reduced Efficiency: Even if immediate catastrophic damage doesn't occur, the presence of liquid in the compressor will reduce its efficiency and shorten its lifespan.

It's crucial to understand that while other safety devices exist within refrigeration systems (such as pressure relief valves), the accumulator’s role in preventing liquid slugging is unique and irreplaceable.

The Importance of Preventative Maintenance for Accumulators

Regular maintenance and inspection of the accumulator are crucial for ensuring its continued effectiveness and the safety of the entire system. This includes:

-

Regular Visual Inspections: Check for any signs of leaks, corrosion, or damage to the accumulator's exterior.

-

Pressure Testing: Periodic pressure testing can identify any weakening or degradation of the accumulator's internal structure.

-

Liquid Level Check: Monitoring the liquid refrigerant level within the accumulator is critical to gauge its proper functioning. An excessively high level might indicate a problem in the system.

-

Cleaning: If the accumulator is accessible, regular cleaning can remove any debris or contaminants that might affect its operation.

Ignoring preventative maintenance can lead to premature failure of the accumulator, rendering it incapable of performing its safety function and increasing the risk of liquid slugging.

Accumulator Sizing and Selection: A Critical Decision

Choosing the right accumulator size is critical for its effective operation. An accumulator that's too small won't be able to accommodate sufficient liquid refrigerant, while one that's too large might occupy unnecessary space and add unnecessary cost. Factors to consider during sizing include:

-

Refrigerant Type: Different refrigerants have different densities and vaporization characteristics, influencing the required accumulator capacity.

-

System Capacity: The larger the refrigeration system, the greater the potential for liquid refrigerant accumulation, requiring a larger accumulator.

-

System Design: The complexity and layout of the refrigeration system affect the potential for liquid refrigerant to enter the suction line.

-

Operating Conditions: Ambient temperature and the refrigeration system's workload influence the amount of liquid refrigerant that might accumulate.

Proper sizing ensures that the accumulator can effectively handle the anticipated liquid refrigerant flow, providing sufficient buffer space to prevent liquid slugging. Incorrect sizing can compromise the safety and efficiency of the entire refrigeration system.

Case Studies: Real-World Consequences of Accumulator Failure

Numerous instances demonstrate the critical role of accumulators in preventing catastrophic failures. While specific details are often confidential for proprietary reasons, the common theme is clear: the absence or malfunction of an accumulator almost always leads to significant damage. These failures often involve:

-

Compressor seizures: Complete destruction of the compressor due to hydraulic lock, requiring costly replacement and extensive system downtime.

-

Valve damage: The intense pressure surges can damage valves, creating leaks and further system instability.

-

Refrigerant leaks: Compromised system integrity leads to refrigerant leaks, posing environmental and safety hazards.

These examples underscore the importance of investing in properly sized and maintained accumulators to prevent potentially devastating and costly failures.

Beyond the Accumulator: A Holistic Approach to Refrigeration System Safety

While the accumulator is critical, a holistic approach to refrigeration system safety is essential. This includes:

-

Regular system inspections: Systematic checks for leaks, corrosion, and other potential issues.

-

Proper installation: Correct installation is crucial for optimal system performance and safety.

-

Trained personnel: Only qualified and trained technicians should handle refrigeration systems to ensure safe operation and maintenance.

-

Appropriate safety measures: Implementing safety protocols, including personal protective equipment (PPE) and emergency procedures.

Conclusion: The Indispensable Role of the Accumulator

In conclusion, the role of accumulators in refrigeration systems cannot be overstated. They are not merely accessories but essential components that safeguard the system from potentially catastrophic liquid slugging. Their presence is not optional; it's mandatory for the safe and efficient operation of any refrigeration system. Regular maintenance, proper sizing, and a comprehensive approach to system safety are crucial to ensure the continued reliability and longevity of your refrigeration system, protecting both your investment and the safety of your personnel. The cost of neglecting accumulator maintenance far outweighs the cost of regular inspections and preventative maintenance. Prioritize accumulator care for a safer and more efficient refrigeration system.

Latest Posts

Latest Posts

-

In Line 6 Them Refers To

Mar 18, 2025

-

Montse Quiere Que Su Dormitorio Elegante

Mar 18, 2025

-

Code Standards And Practices 3 Lesson 1

Mar 18, 2025

-

Mr Barker Enjoys A Comfortable Retirement Income

Mar 18, 2025

-

Afterlife The Strange Science Of Decay Answer Key

Mar 18, 2025

Related Post

Thank you for visiting our website which covers about All Refrigeration Systems Must Have Accumulators To Operate Safely . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.