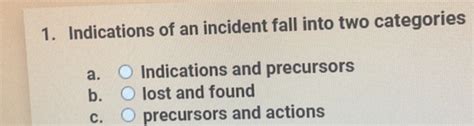

Indications Of An Incident Fall Into Two Categories

Onlines

Mar 10, 2025 · 6 min read

Table of Contents

Indications of an Incident Fall into Two Categories: A Comprehensive Guide

Accidents and incidents, while often used interchangeably, represent distinct occurrences. Understanding the nuances between these terms is crucial, especially in fields like safety management, healthcare, and incident reporting. This article delves deep into the two primary categories indicating an incident: direct indications and indirect indications. We'll explore each category in detail, providing real-world examples and practical strategies for identifying and mitigating potential incidents.

Direct Indications: The Clear and Present Danger

Direct indications of an incident are readily observable and unequivocally point towards a potential or actual hazardous event. These are the “smoking guns” of incident investigation – clear evidence that something went wrong, or is about to. They leave little room for interpretation and demand immediate attention.

1. Physical Evidence: The Visible Signs of Trouble

This category encompasses all the tangible signs of an incident, ranging from the minor to the catastrophic.

-

Damage to property: This can be anything from a small scratch on a machine to a major structural collapse. A broken window, a damaged vehicle, or a spilled chemical are all direct indicators. The extent of the damage often correlates with the severity of the incident.

-

Injuries to personnel: Physical harm to individuals is a clear and urgent direct indication. This includes cuts, bruises, burns, fractures, and even fatalities. The severity and type of injury provide crucial information about the incident's nature.

-

Equipment malfunction: A machine that unexpectedly shuts down, produces faulty output, or displays warning lights is a direct indication of a potential incident. This extends to tools, vehicles, and any piece of equipment involved in a process.

-

Environmental contamination: Spills, leaks, and releases of hazardous substances are obvious direct indicators. This includes chemical spills, oil leaks, radioactive contamination, and the release of toxic gases. The immediate impact on the environment and potential long-term effects need careful assessment.

-

Fire or explosion: These are unequivocal indications of a severe incident. The source of ignition, the extent of the damage, and the substances involved are all crucial pieces of information for investigation.

Example: A worker sustains a laceration to their hand while operating a wood chipper. The injury (direct physical evidence) clearly indicates a failure in safety procedures or equipment malfunction (another direct indication).

2. Witness Accounts: Eyewitnesses to the Event

Eyewitness testimony, while subjective, plays a crucial role in establishing a chain of events and identifying contributing factors.

-

Immediate reports from those present: These accounts, often made immediately after the incident, provide valuable insight into the unfolding of events. The closer the witness was to the incident, the more reliable their testimony tends to be.

-

Documented observations: Written records, security camera footage, and other forms of documented observations provide objective evidence corroborating witness accounts.

-

Consistent narratives: Multiple witnesses providing similar accounts strengthen the reliability of the information gathered. Discrepancies, however, should be carefully investigated to determine their source.

Example: Several employees witness a forklift driver lose control and crash into a stack of pallets. Their consistent descriptions of the event, along with the physical damage to the forklift and pallets, constitute strong direct indications of an incident.

Indirect Indications: The Subtle Clues and Warning Signs

Indirect indications are less obvious and may require more investigation to link them to a potential incident. These are the "early warning signs" that, if ignored, can lead to more serious consequences. They often point towards underlying systemic issues or latent failures that increase the likelihood of an incident occurring.

1. Near Misses and Potential Hazards: Learning from the Avoided Disaster

Near misses are incidents that almost happened but didn't result in actual harm or damage. Analyzing near misses provides invaluable insight into potential hazards and allows for preventative measures before an actual incident occurs.

-

Identifying recurring patterns: Similar near misses occurring repeatedly indicate a systematic problem that needs addressing. This may involve inadequate training, faulty equipment, or unsafe work practices.

-

Analyzing root causes: Investigating near misses helps uncover the underlying causes that almost resulted in an incident. This prevents a repetition of the same event leading to a more serious outcome.

Example: A worker nearly drops a heavy object, but manages to catch it before it falls. This near miss indicates a potential hazard related to lifting procedures or equipment, requiring immediate attention to improve safety practices.

2. Changes in Performance or Behavior: The Subtle Shift

Changes in performance or behavior can be subtle indicators of underlying issues that may lead to incidents. These changes may be exhibited by individuals, equipment, or the overall system.

-

Increased error rates: A significant increase in errors or mistakes in a specific task or process might suggest underlying problems with training, procedures, or equipment.

-

Decreased productivity: A drop in productivity could be a sign of fatigue, inadequate training, or equipment malfunction – all potential precursors to incidents.

-

Changes in equipment performance: Deviations from expected equipment performance, such as increased noise, vibrations, or temperature fluctuations, can be indicative of impending failure.

-

Changes in worker behavior: Increased complaints, absenteeism, or a shift in attitude can be indicators of underlying problems affecting worker morale and safety.

Example: A machine operator consistently produces substandard work, and the quality control department notes a recent increase in faulty products. This change in performance may indicate a need for equipment maintenance, operator retraining, or a review of the production process.

3. Audit Findings and Inspections: The Formal Assessment

Formal assessments, such as audits and inspections, can identify potential hazards and deficiencies that might lead to incidents. These assessments offer a systematic way to identify both direct and indirect indications.

-

Non-conformances: Failures to meet established standards or regulations are clear indicators of potential hazards. These non-conformances could relate to safety procedures, equipment maintenance, or environmental protection.

-

Corrective actions: The need for corrective actions to address deficiencies identified during inspections indicates underlying problems that require immediate attention.

-

Recommendations for improvement: Suggestions for improvement highlight areas where systems can be strengthened to prevent future incidents.

Example: A safety audit reveals inadequate emergency lighting in a manufacturing facility. This deficiency constitutes an indirect indication because it increases the risk of injury or death in the event of a fire or other emergency.

4. Data Analysis and Trending: Unveiling Patterns and Predictions

Analyzing incident data over time can reveal patterns and trends that highlight areas of increased risk. This data-driven approach allows for proactive measures to prevent future incidents.

-

Frequency of incidents: An increase in the frequency of a specific type of incident suggests the need for focused intervention in that area.

-

Severity of incidents: A trend towards more severe incidents indicates a potential escalation in risk that needs immediate attention.

-

Location of incidents: Clustering of incidents in a specific location or area of operations indicates a potential localized hazard.

Example: Analysis of incident reports over the past year reveals a significant increase in slips, trips, and falls in a particular section of a warehouse. This trend indicates the need for improved housekeeping or flooring maintenance in that specific area.

Conclusion: Proactive Identification for a Safer Environment

Identifying both direct and indirect indications of incidents is crucial for establishing a proactive safety culture. By combining a vigilant approach to observation with systematic data analysis, organizations can significantly reduce the likelihood of accidents and incidents, leading to a safer and more productive work environment. Understanding the subtle nuances between direct and indirect indicators empowers proactive intervention, turning potential disasters into valuable learning opportunities. This comprehensive approach to incident prevention promotes not only safety but also operational efficiency and overall organizational success.

Latest Posts

Latest Posts

-

Unit Chemical Bonding Covalent Bonding Ws 3

Mar 10, 2025

-

Gizmos Student Exploration Adding Vectors Answer Key

Mar 10, 2025

-

Unit 9 Progress Check Mcq Ap Lang

Mar 10, 2025

-

Allow A Larger Space Cushion Than Usual When Stopping

Mar 10, 2025

-

An Automobile Manufacturer Sold 30000 New Cars

Mar 10, 2025

Related Post

Thank you for visiting our website which covers about Indications Of An Incident Fall Into Two Categories . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.