Dell Roadmap Of A Digital Supply Chain Transformation

Onlines

Mar 26, 2025 · 5 min read

Table of Contents

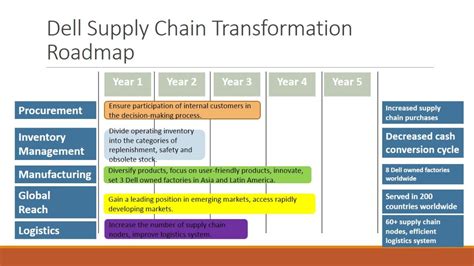

Dell's Roadmap to Digital Supply Chain Transformation: A Deep Dive

Dell Technologies, a global leader in the technology industry, has embarked on an ambitious journey of digital supply chain transformation. This isn't just about implementing new technologies; it's a fundamental shift in how Dell operates, aiming for greater agility, efficiency, and resilience in the face of ever-increasing market demands and global uncertainties. This comprehensive article delves deep into Dell's roadmap, exploring the key strategies, technologies, and challenges involved in this massive undertaking.

The Imperative for Transformation: Why Dell Embraced Digitalization

Dell's traditional supply chain, while successful for many years, faced increasing pressure from several factors:

- Increased Market Volatility: Rapid technological advancements, shifting customer preferences, and geopolitical instability created unpredictable demand patterns. The old model struggled to adapt quickly enough.

- Global Supply Chain Disruptions: Events like the pandemic exposed vulnerabilities in global supply chains, highlighting the need for greater resilience and diversification.

- Growing Customer Expectations: Customers now expect faster delivery times, personalized products, and greater transparency throughout the supply chain.

- The Rise of Data and Analytics: The explosion of data offered an unprecedented opportunity to gain deeper insights into supply chain operations and improve decision-making.

These challenges spurred Dell to radically rethink its supply chain operations, leading to a comprehensive digital transformation initiative. This wasn't a simple upgrade but a complete overhaul, integrating various technologies and strategies to create a more responsive and intelligent network.

Pillars of Dell's Digital Supply Chain Transformation

Dell's roadmap isn't a single, monolithic project; rather, it's built on several interconnected pillars:

1. Data-Driven Decision Making: The Foundation of Intelligence

At the heart of Dell's transformation is a commitment to data-driven decision-making. This involves:

- Real-time Visibility: Implementing advanced tracking and monitoring systems across the entire supply chain provides complete visibility into inventory levels, shipment status, and potential disruptions. This real-time data empowers proactive interventions.

- Predictive Analytics: Leveraging machine learning and AI algorithms to forecast demand, optimize inventory levels, and anticipate potential bottlenecks. This allows for more accurate planning and resource allocation.

- Advanced Data Analytics: Using sophisticated analytical tools to identify trends, patterns, and anomalies within the supply chain, leading to continuous improvement and optimization. This goes beyond basic reporting and delves into root cause analysis for significant efficiency gains.

2. Automation and Robotics: Streamlining Operations

Automation plays a crucial role in improving efficiency and reducing costs. Dell has invested heavily in:

- Robotics Process Automation (RPA): Automating repetitive tasks such as order processing, invoice generation, and data entry, freeing up human employees for more strategic roles.

- Warehouse Automation: Implementing automated guided vehicles (AGVs), robotic picking and packing systems, and automated storage and retrieval systems (AS/RS) to enhance warehouse efficiency and speed.

- Supply Chain Optimization Software: Utilizing advanced software solutions to optimize transportation routes, warehouse layouts, and inventory management, minimizing costs and maximizing throughput.

3. Supply Chain Collaboration: Building Stronger Ecosystems

Dell recognizes the importance of collaboration with its partners and suppliers. This involves:

- Enhanced Supplier Relationships: Fostering closer relationships with key suppliers through enhanced communication, data sharing, and joint planning. This leads to better coordination and greater responsiveness.

- Collaborative Planning, Forecasting, and Replenishment (CPFR): Implementing CPFR processes to improve forecast accuracy, reduce inventory levels, and enhance responsiveness to changing demand.

- Blockchain Technology: Exploring the potential of blockchain to enhance transparency, traceability, and security throughout the supply chain. This is particularly important for tracking components and ensuring authenticity.

4. Cloud-Based Technologies: Enhancing Agility and Scalability

The cloud plays a vital role in enabling agility and scalability:

- Cloud-Based Supply Chain Platforms: Migrating to cloud-based platforms for supply chain management, enabling greater flexibility, scalability, and accessibility.

- Cloud-Based Analytics: Utilizing cloud-based analytics platforms to process and analyze large volumes of data, providing valuable insights for decision-making.

- Cloud-Based Collaboration Tools: Employing cloud-based collaboration tools to enhance communication and information sharing among stakeholders throughout the supply chain.

5. Sustainability and Ethical Sourcing: Building a Responsible Supply Chain

Dell's transformation also incorporates a strong focus on sustainability and ethical sourcing:

- Sustainable Packaging: Utilizing eco-friendly packaging materials and reducing waste throughout the supply chain.

- Responsible Sourcing: Ensuring that components and materials are sourced ethically and sustainably, minimizing environmental impact and promoting fair labor practices.

- Carbon Footprint Reduction: Implementing measures to reduce the carbon footprint of its supply chain operations, contributing to a more sustainable future.

Technologies Driving Dell's Transformation

Several cutting-edge technologies are crucial to Dell's digital supply chain transformation:

- Artificial Intelligence (AI): Used for predictive analytics, demand forecasting, anomaly detection, and optimization of various supply chain processes.

- Machine Learning (ML): Enables the continuous improvement of algorithms and models used for forecasting, optimization, and anomaly detection.

- Internet of Things (IoT): Provides real-time visibility into the movement and status of goods throughout the supply chain, enhancing tracking and monitoring capabilities.

- Blockchain: Enhances transparency, traceability, and security of transactions and information throughout the supply chain.

- Cloud Computing: Provides scalable, flexible, and cost-effective infrastructure for data storage, processing, and application deployment.

Challenges and Considerations

Despite the significant progress, Dell faces several challenges in its transformation journey:

- Data Integration and Management: Integrating data from disparate sources across the entire supply chain can be complex and challenging.

- Change Management: Successfully implementing new technologies and processes requires significant changes in organizational culture and employee skills.

- Cybersecurity: Protecting sensitive data and systems from cyber threats is paramount in a highly interconnected digital environment.

- Supply Chain Resilience: Maintaining resilience in the face of unforeseen disruptions and geopolitical instability remains a critical challenge.

- Cost of Implementation: Implementing new technologies and processes can be expensive, requiring significant investments in infrastructure and talent.

Conclusion: A Journey of Continuous Improvement

Dell's digital supply chain transformation is an ongoing journey, not a destination. The company's commitment to data-driven decision-making, automation, collaboration, cloud technologies, and sustainability positions it well for future success. While challenges remain, Dell's proactive approach and investment in cutting-edge technologies suggest a strong future in a rapidly evolving global landscape. The company's success will serve as a case study for other organizations seeking to modernize their supply chains and enhance their competitiveness in the digital age. The roadmap is dynamic and adapts to evolving technological advancements and market changes, solidifying Dell's position as a leader in innovative supply chain management. The focus on continuous improvement ensures that Dell remains agile, responsive, and resilient in the face of future uncertainties.

Latest Posts

Latest Posts

-

Which Of The Statements Below Explains The Accounting Cycle

Mar 28, 2025

-

The Debt Snowball Worksheet Answers Pdf

Mar 28, 2025

-

Emotional Abuse Can Include All Of The Following Except

Mar 28, 2025

-

Chapter 22 Section 4 1968 A Tumultuous Year

Mar 28, 2025

-

Geometry Unit 4 Test Answer Key Pdf

Mar 28, 2025

Related Post

Thank you for visiting our website which covers about Dell Roadmap Of A Digital Supply Chain Transformation . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.